Introduction

BRM (Bottleneck Resolution Method) is a Process Improvement strategy to enhance service and administrative processes. It offers a pragmatic way to enable team discussions to map out the current process and to identify and implement opportunities for improvement.

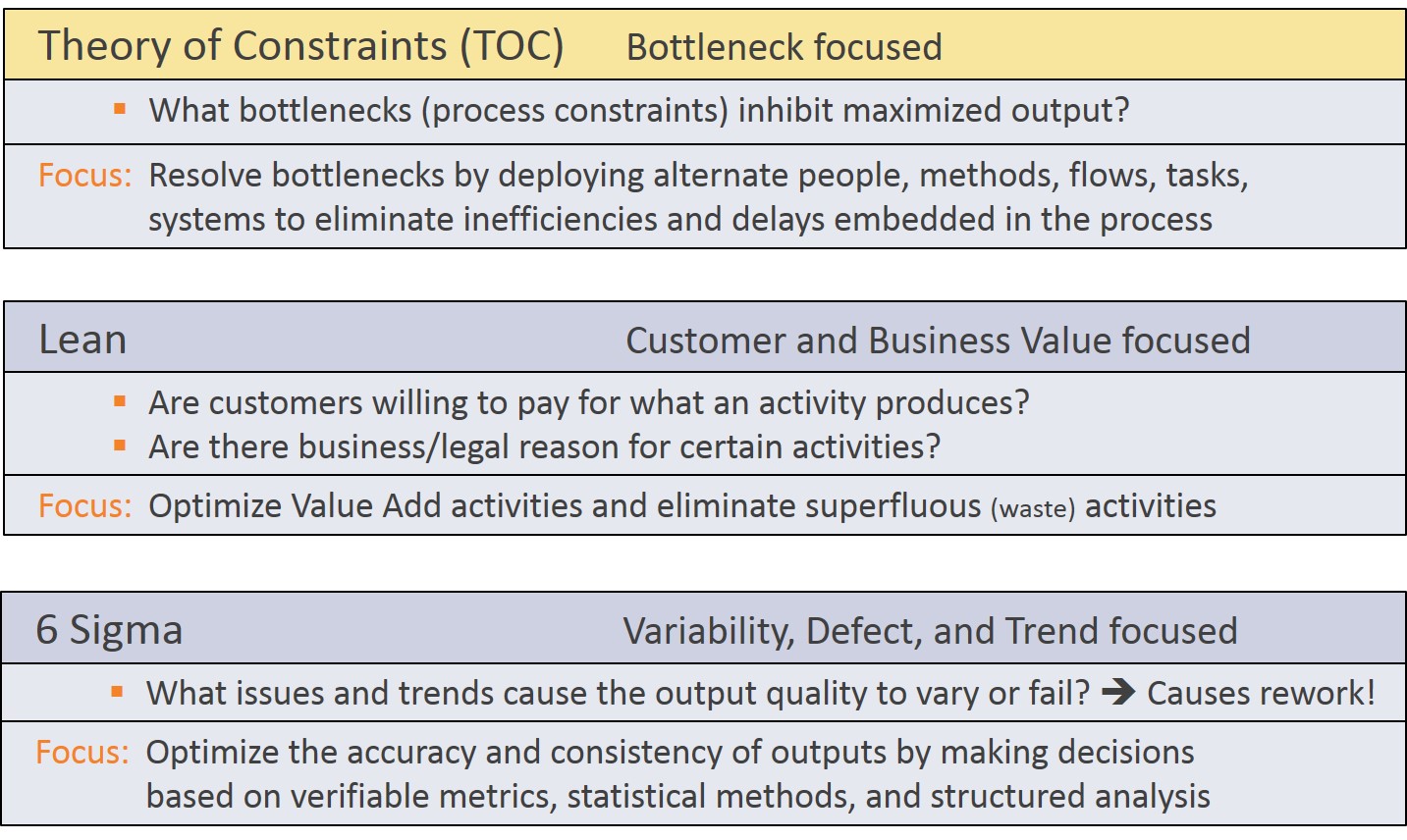

BRM combines concepts from other Process Improvement methods, including bottleneck resolution (Theory Of Constraints - TOC), non-value-add elimination (Lean), and defect reduction (6 Sigma). However, BRM avoids the more complex aspects of those methods to create a more streamlined approach focused on what service and business teams can feasibly improve.

The method can be applied without hiring experts, such as 6 Sigma black belts. Nevertheless, it is good to use a facilitator, for example a team member with good personal skills. This toolkit provides guidance for facilitators to enable BRM within their organization.

While BRM promotes using metrics, this is not required to gain significant impact on service and administrative processes. Nevertheless, it helps if facilitators have an understanding of metrics, so they can recognize when introducing some metrics might be useful.

While this toolkit can be used to improve service and administrative processes in any industry, the target audience is the healthcare provider community. As such, many of the incorporated examples are health care related.

What is a Process?

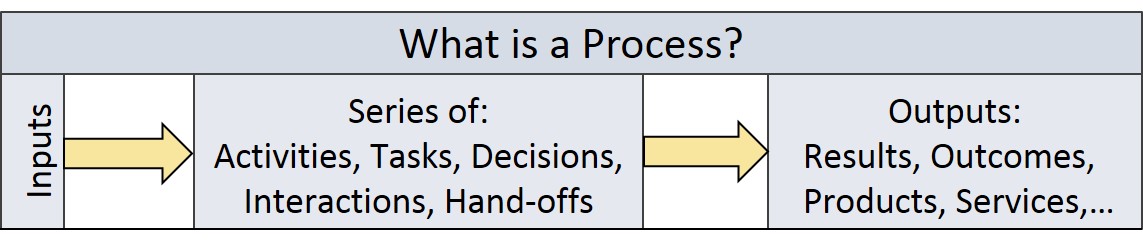

A process can be defined as a series of activities, tasks, decisions, interactions and handoffs executed by resources to convert a set of inputs into a set of outputs. Resources refers to employees, machines, computers, and other systems.

This definition of process may seem less apparent for service and administrative processes than for manufacturing processes that create products, but this definition helps in understanding Process Improvement. Consider for instance these two examples:

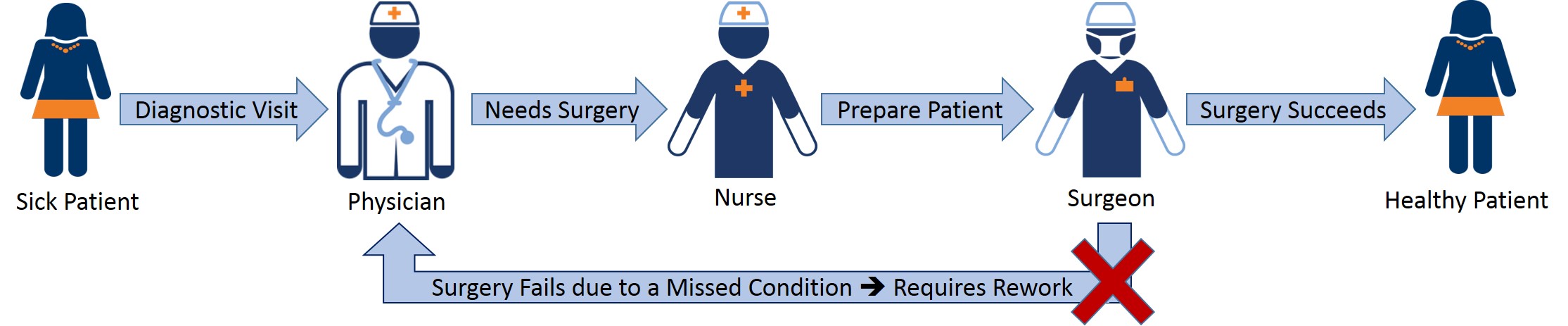

- A clinical service process can convert a sick patient (input) into a healthy patient (output) through a series of clinical treatments (activities and decisions).

- An administrative process can convert completed treatments (inputs) into invoices (outputs) for insurance companies and other payors through administrative activities.

Processes can be executed by individuals or teams. Teams can operate within a single function (functional) or across multiple functions (cross-functional), and within one or across multiple organizations. Some processes are formalized in procedures, others are informal, or consist of a mix of formal and informal procedures. BRM works best for team-based processes.

Why Process Improvement?

Process Improvement can increase the quantity and quality of what a business produces at a decreased cost per unit of output. The improvements can free up resource capacity that can be invested in growing the business and its competitive advantage. This will enable a culture that increases profitability, boosts impact, and enhances employee growth.

Processes may be inefficient and prone to defects (process and system flaws or failures, human errors, mistakes, etc.), which reduces the quantity and quality of the outputs. The more complex the process, and the more people involved, the more issues tend to arise. Process Improvement can help in identifying and resolving inefficiencies and defects.

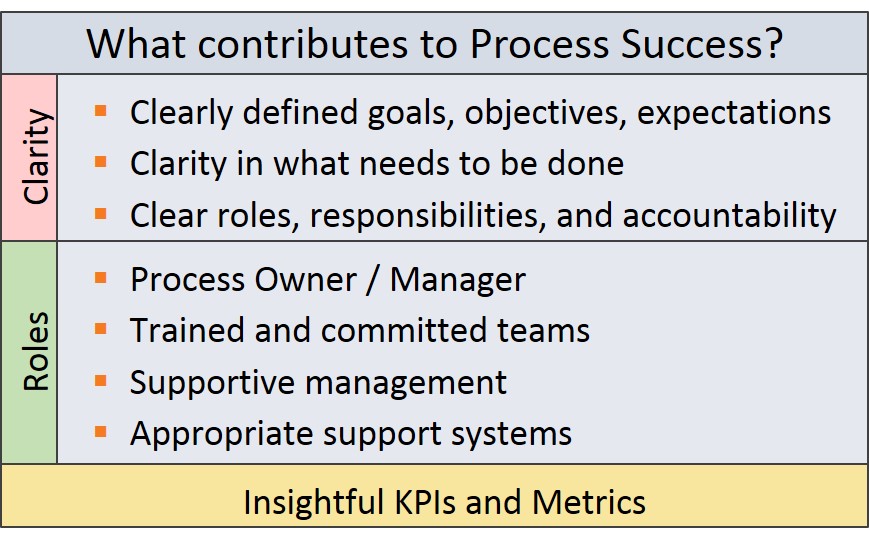

Clarity is a core driver for the successful execution of a process. Processes need clearly defined goals, objectives, and expectations of what needs to be accomplished; clarity in what needs to be done to create the desired outputs; and clear roles with well defined responsibilities and accountability. Process Improvement can assist in establishing clarity.

From the roles perspective, successful processes typically have a process owner and manager who are supportive of their team; a trained and committed team that is motivated to execute the process; and support systems that appropriately assist what the team is supposed to do. Process Improvement can enable the clear definition and alignment of the roles.

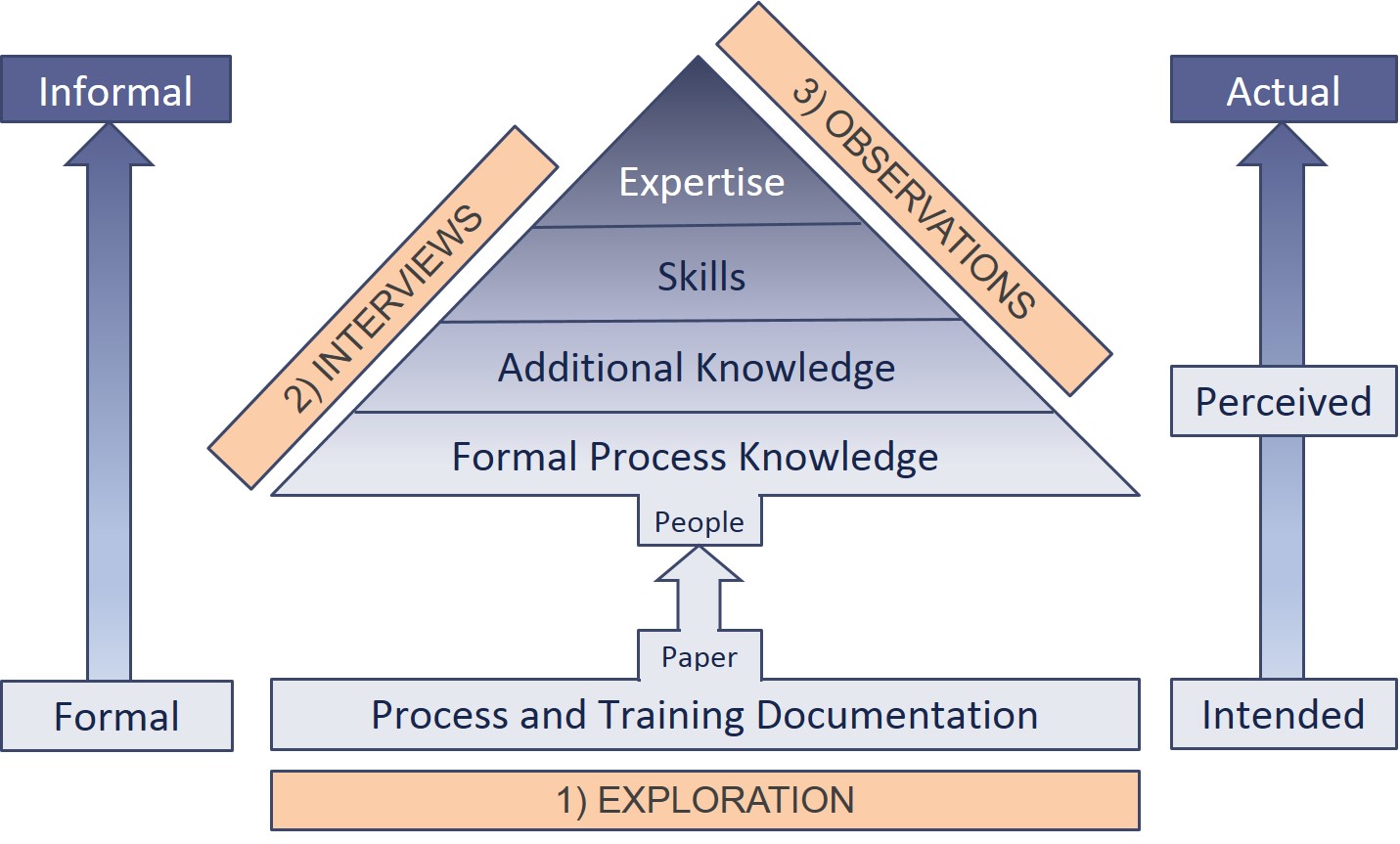

The Lifecycle of a Process

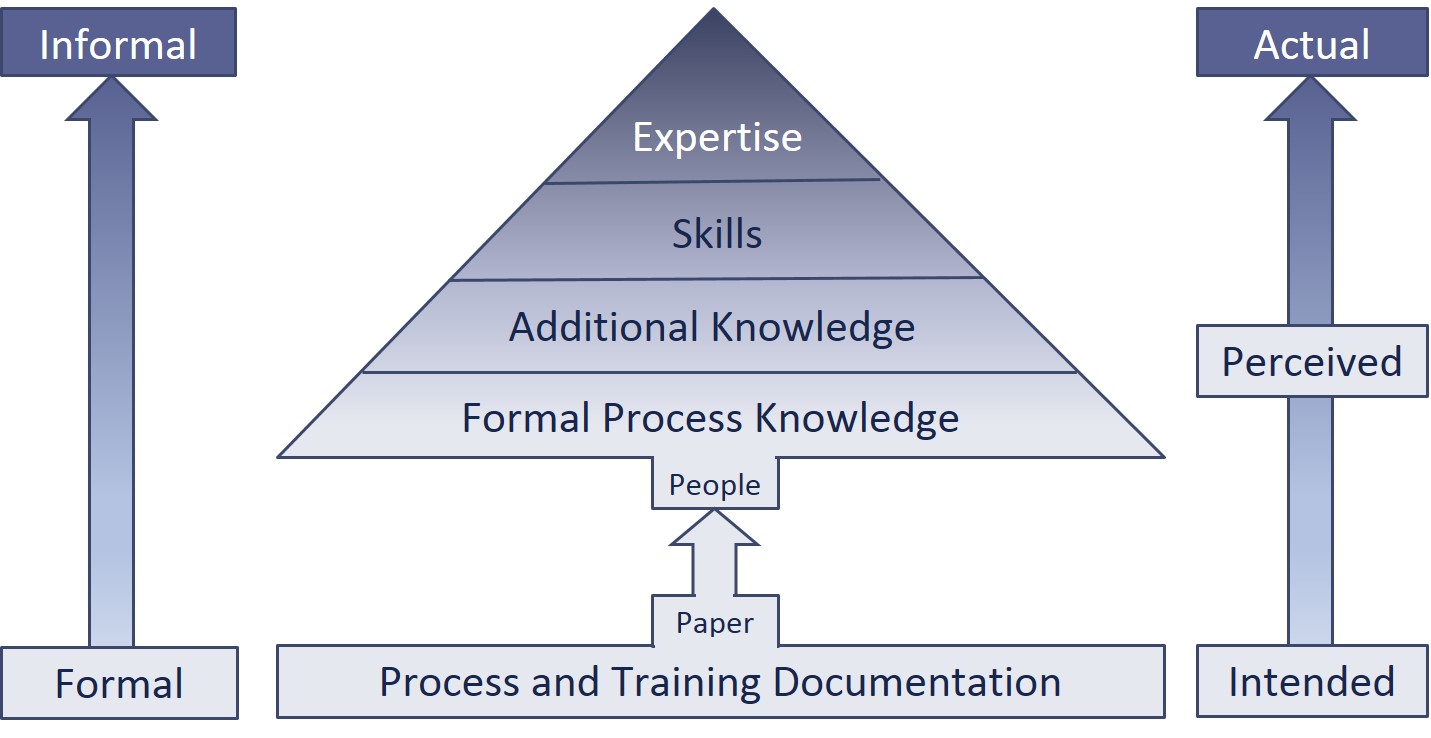

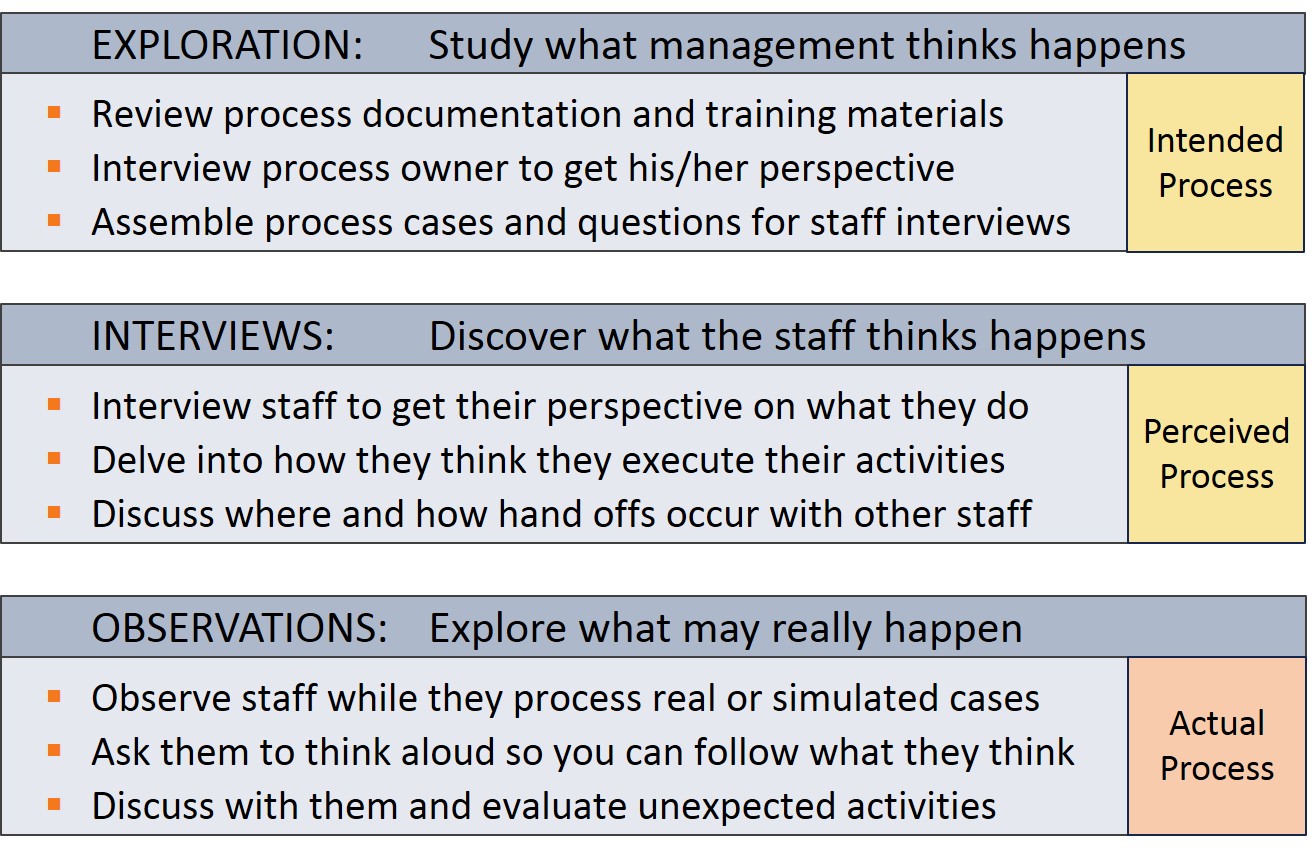

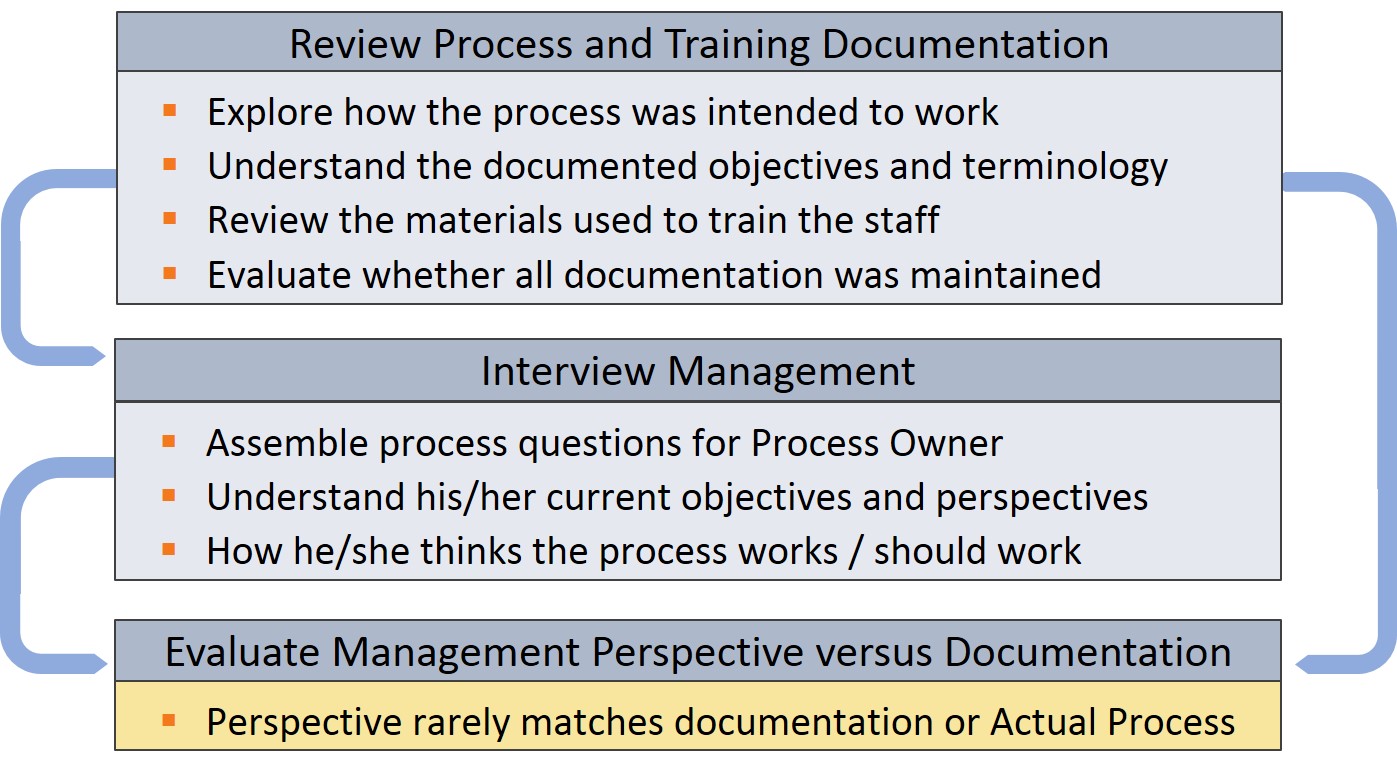

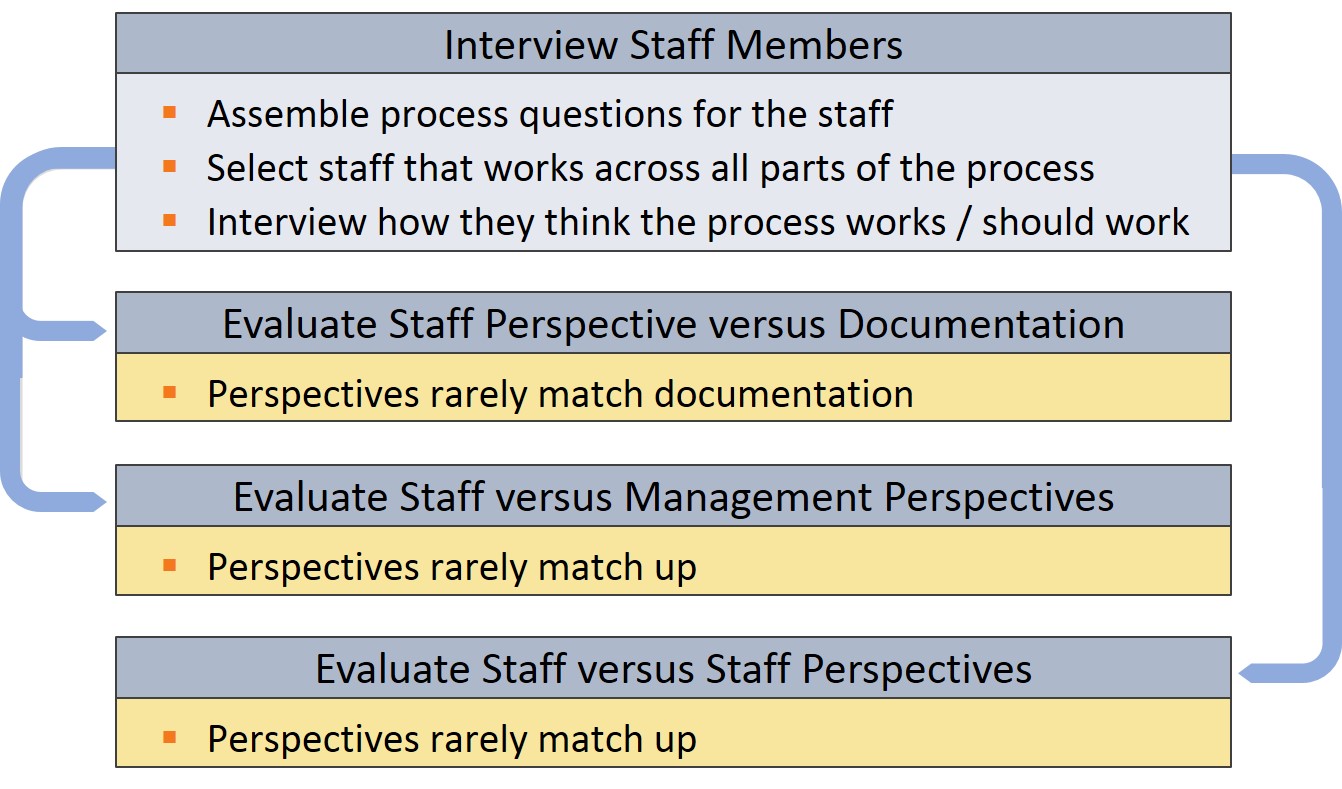

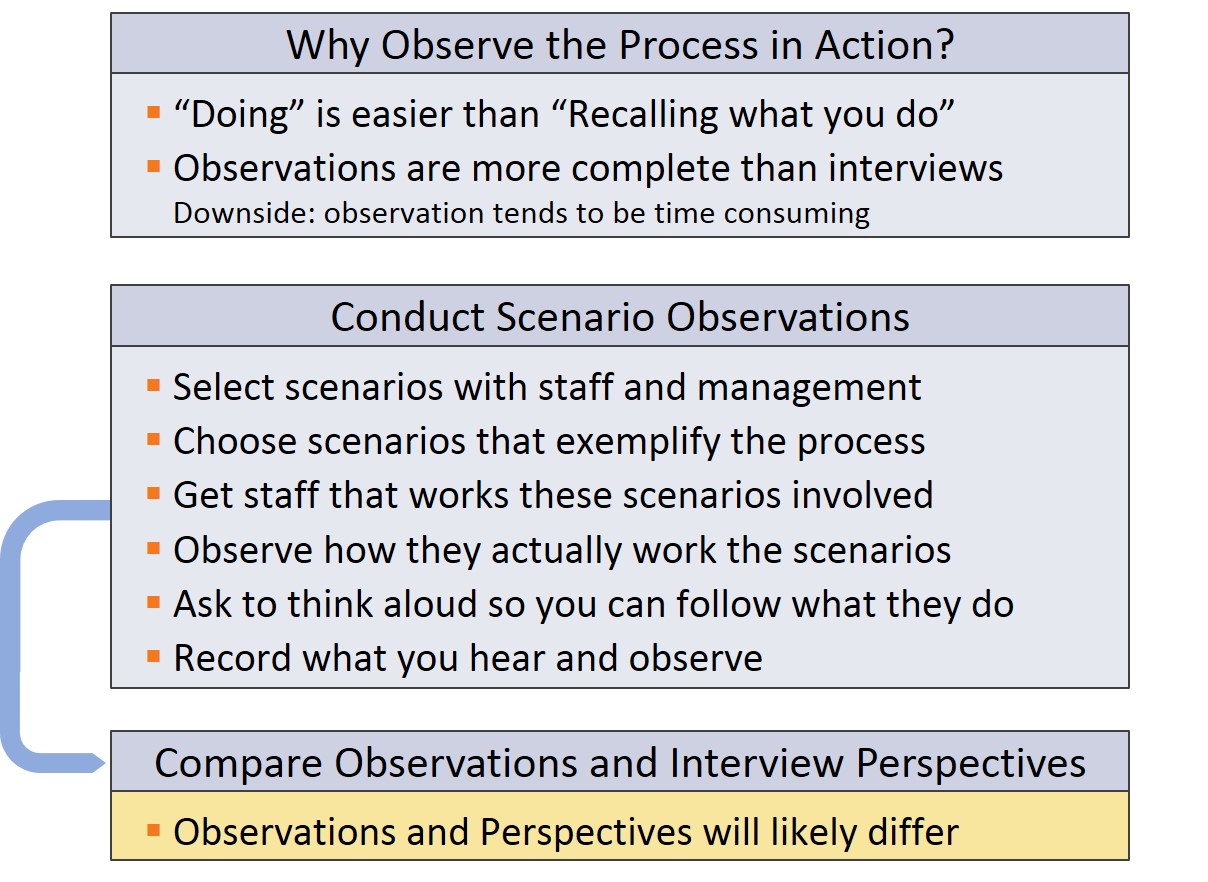

When a process is initiated, the intended design is typically formalized in process and training documentation written by managers, process teams, and process designers. This documentation can be used to train the initial process team, and people who join this team later on. However, over time the process will likely begin to deviate from how it was originally documented:

- Deviations may be introduced deliberately. For instance, adaptations will need to be made to refine the process. However, if such changes don't get documented, they become an informal part of the process that people might not be aware of.

- Adaptations may also be introduced inadvertently. People tend to incorporate their knowledge, skills, and experience to make their work efficient. They introduce shortcuts, add steps they think are missing, or skip steps they deem irrelevant. This adds informal aspects to the process that the manager and other team members might not know about.

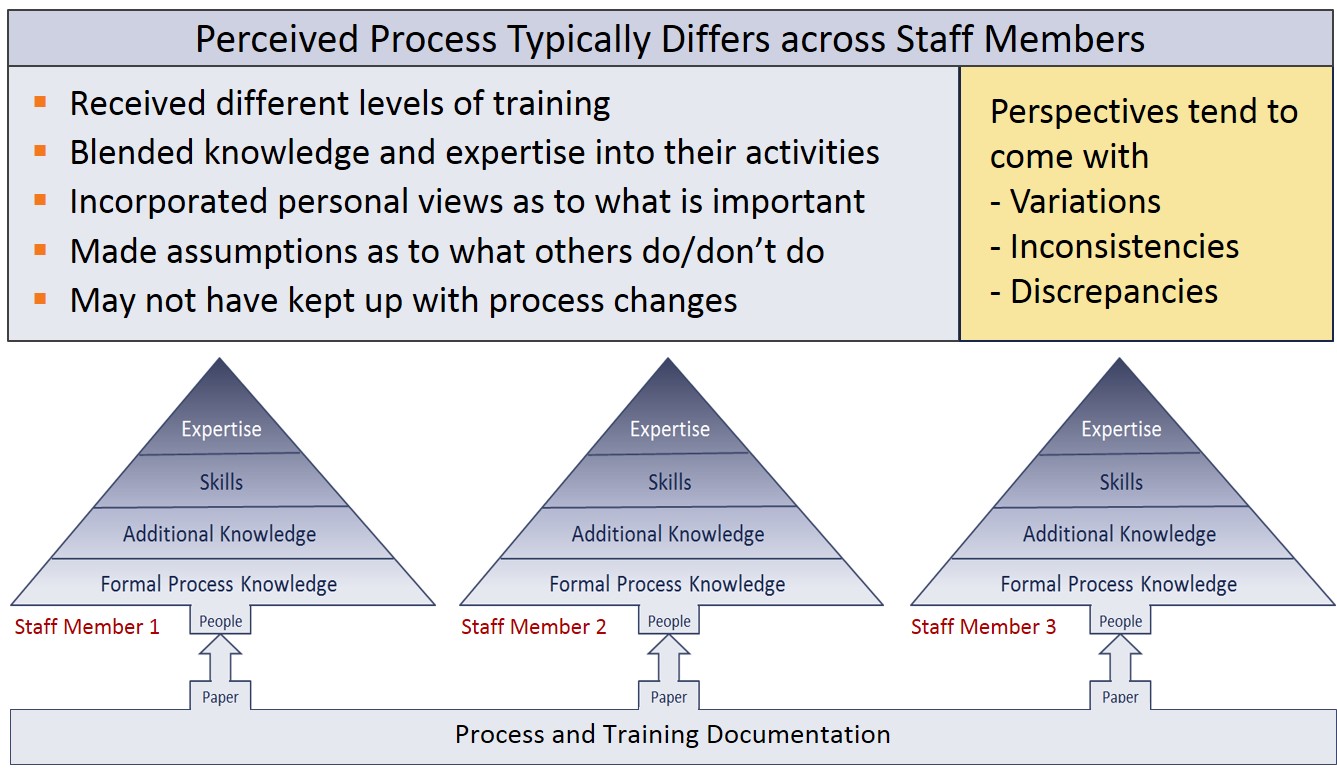

Over time, the process will become more informal. Perceptions of the manager and team members of how things work will begin to differ, because people often don't tell others how they have incorporated their knowledge, skills and expertise to improve what they do.

This divergence gets exacerbated by the fact that people tend to make assumptions about what others do without verification. As assumptions may be incorrect, the way the manager and team members perceive the process will likely not match the real process.

It may seem that this evolution would be detrimental to the results of a process, but attempts to suppress the progression will likely have adverse and undesirable consequences. For instance, it will create discord and demotivation, as people want to use their knowledge and expertise. Moreover, the informal activities added to a process by the employees often make processes more efficient.

In a manufacturing environment it is fairly easy to justify that all activities should be executed exactly to design specifications, as you don't want the products to vary in quality. However, in service and administrative processes the outputs aren't as clearly defined, and employees tend to be much less accepting of strict controls that stifle their personalized input.

Nevertheless, to avoid that the outputs end up deviating from what is required, it is imperative to get everyone back on one page on a regular basis. A process will work better and more consistently if the manager and team are aware of how the process actually works and know what others do. This is where the BRM Process Improvement strategy can help.

Overview of the Bottleneck Resolution Method

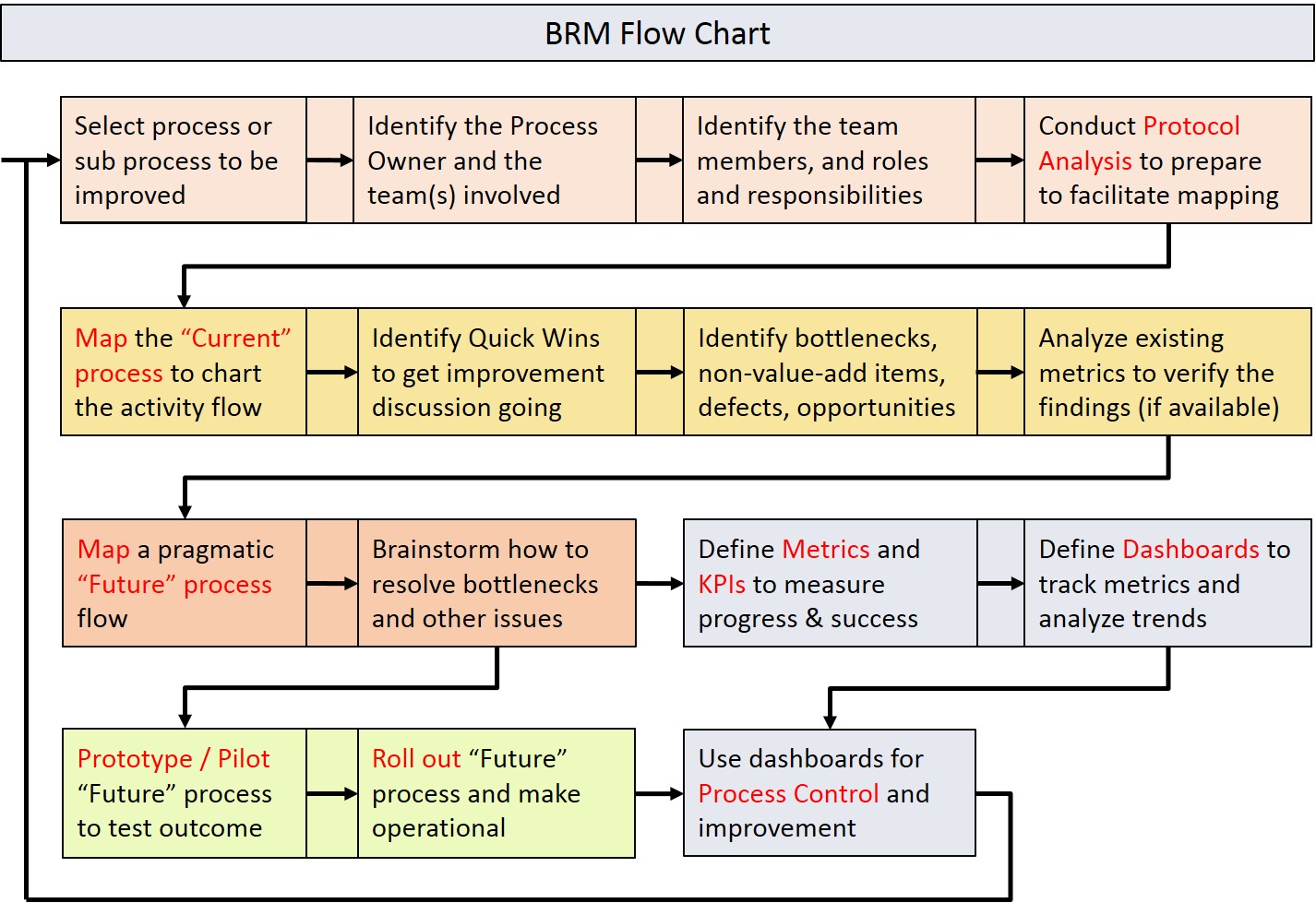

To learn how BRM works, first read the sections below, and then read the tabs of this toolkit in the order listed. Each tab is a course that explains a major BRM topic. As the content is rich in information, we advise reading the tabs in multiple sittings. The graphic below provides a flow chart of the full BRM Process Improvement strategy, based on all topics covered in this toolkit.

Process Selection

For process Improvement to work, it is important to get off to a good start. It works best if the team can successfully improve some simpler processes, before expanding the effort to complex processes. This enables that the team gets excited about the results and stays motivated to continue. The first step is therefore to select processes where improvement has a reasonable chance of success.

Select the "Process Selection" tab to learn about tools that can enable the team to make a good selection.

Process Mapping

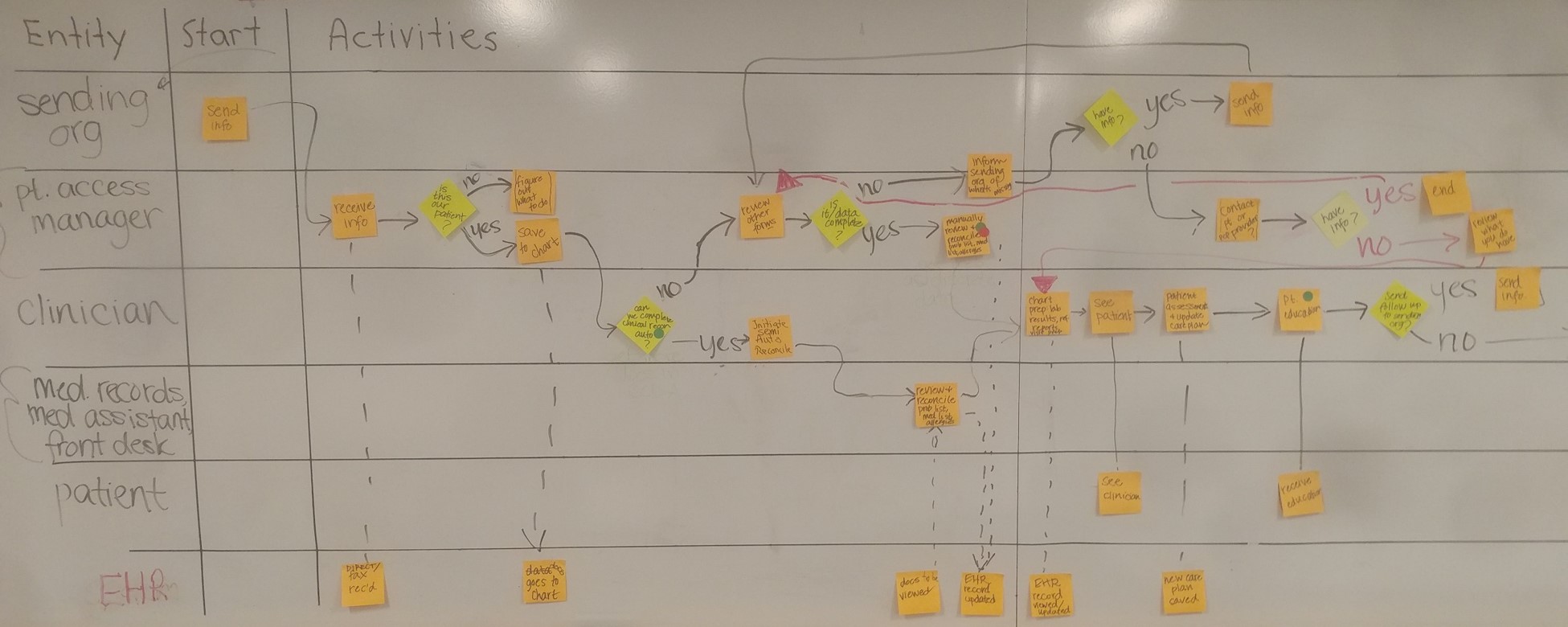

After Process Selection, the next step is Process Mapping. During a mapping session, the team will map their activities. The aim is to get everyone on one page, to align the perspectives, and to establish mutual understanding of how the process really works, as the starting point to make realistic improvements everyone can agree to.

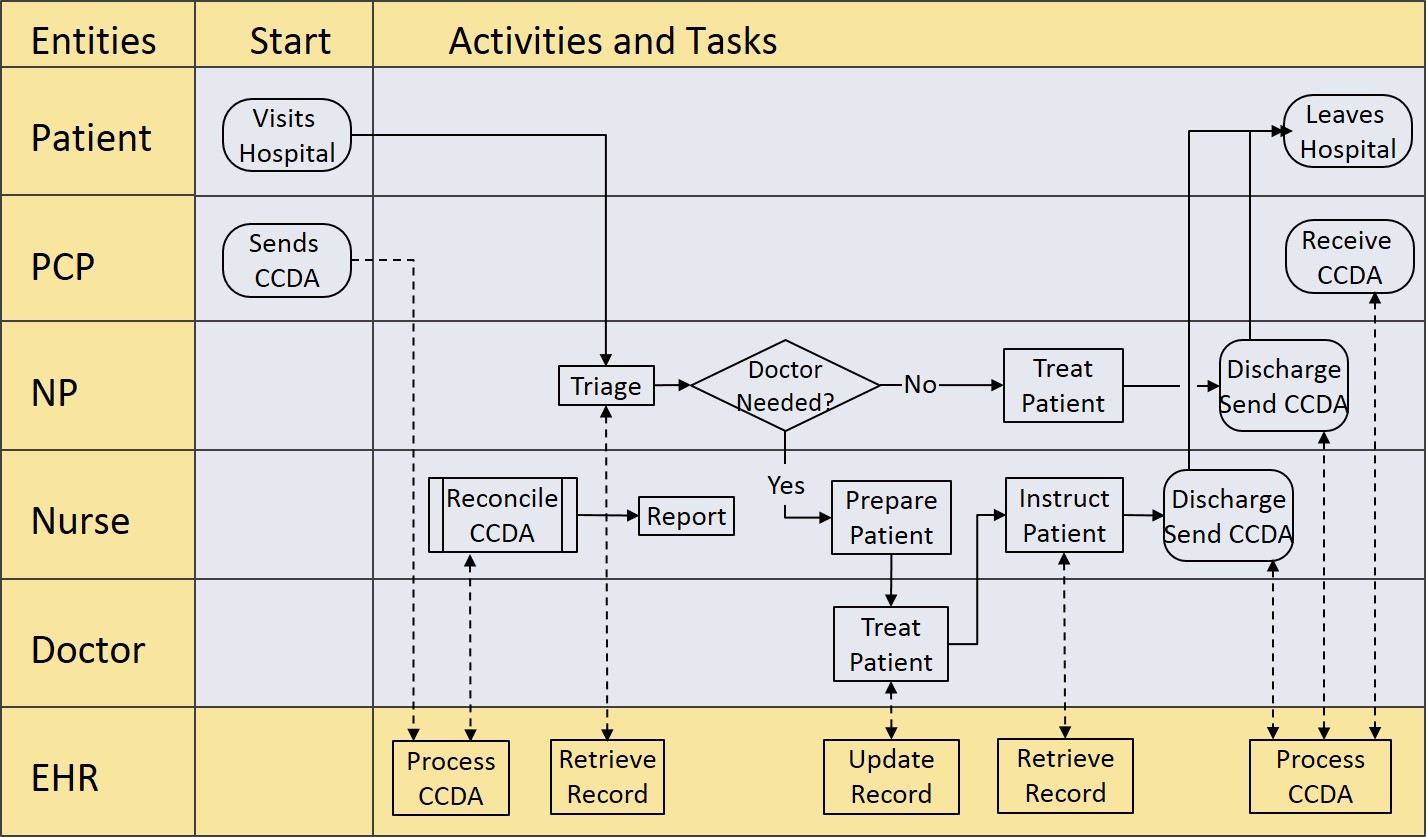

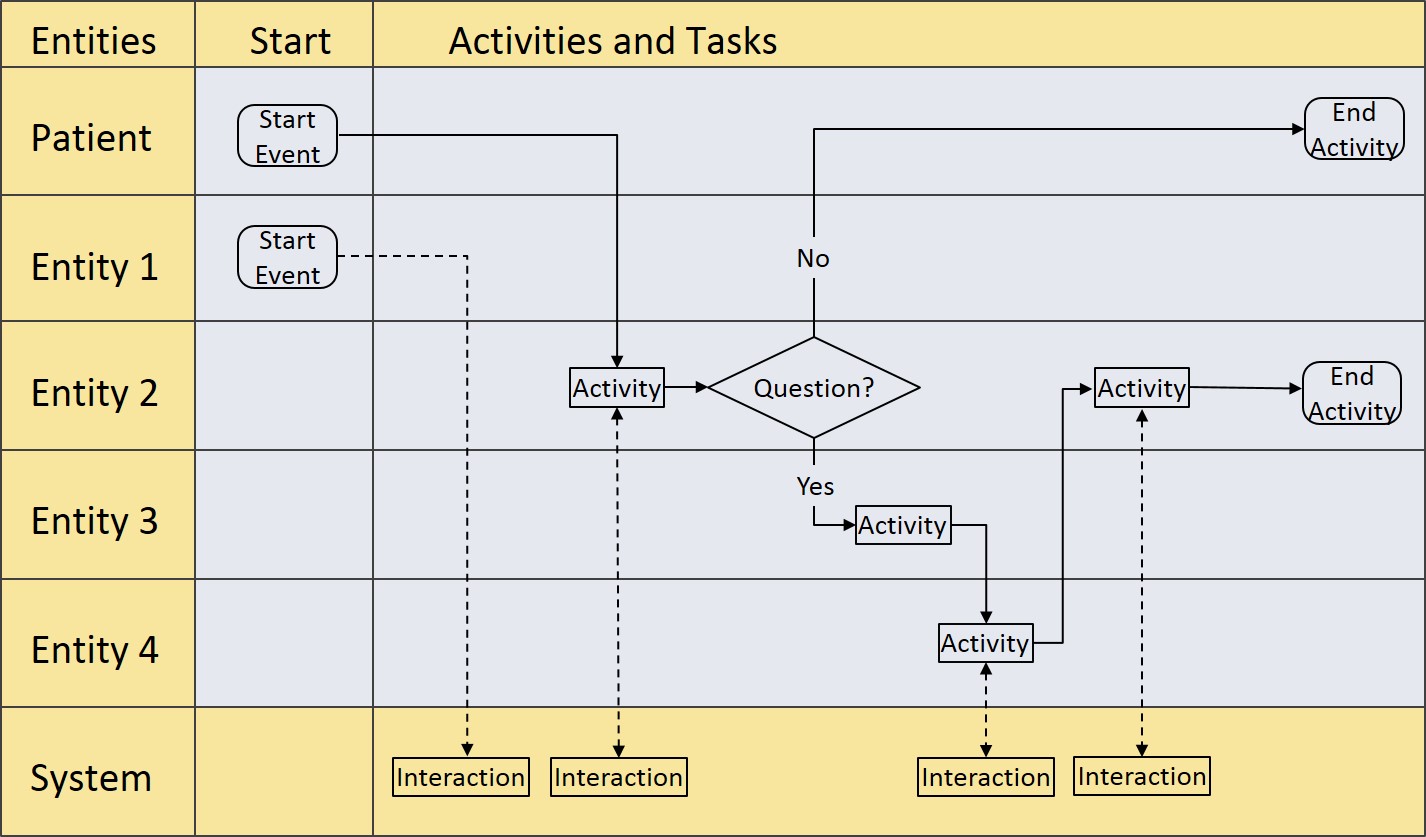

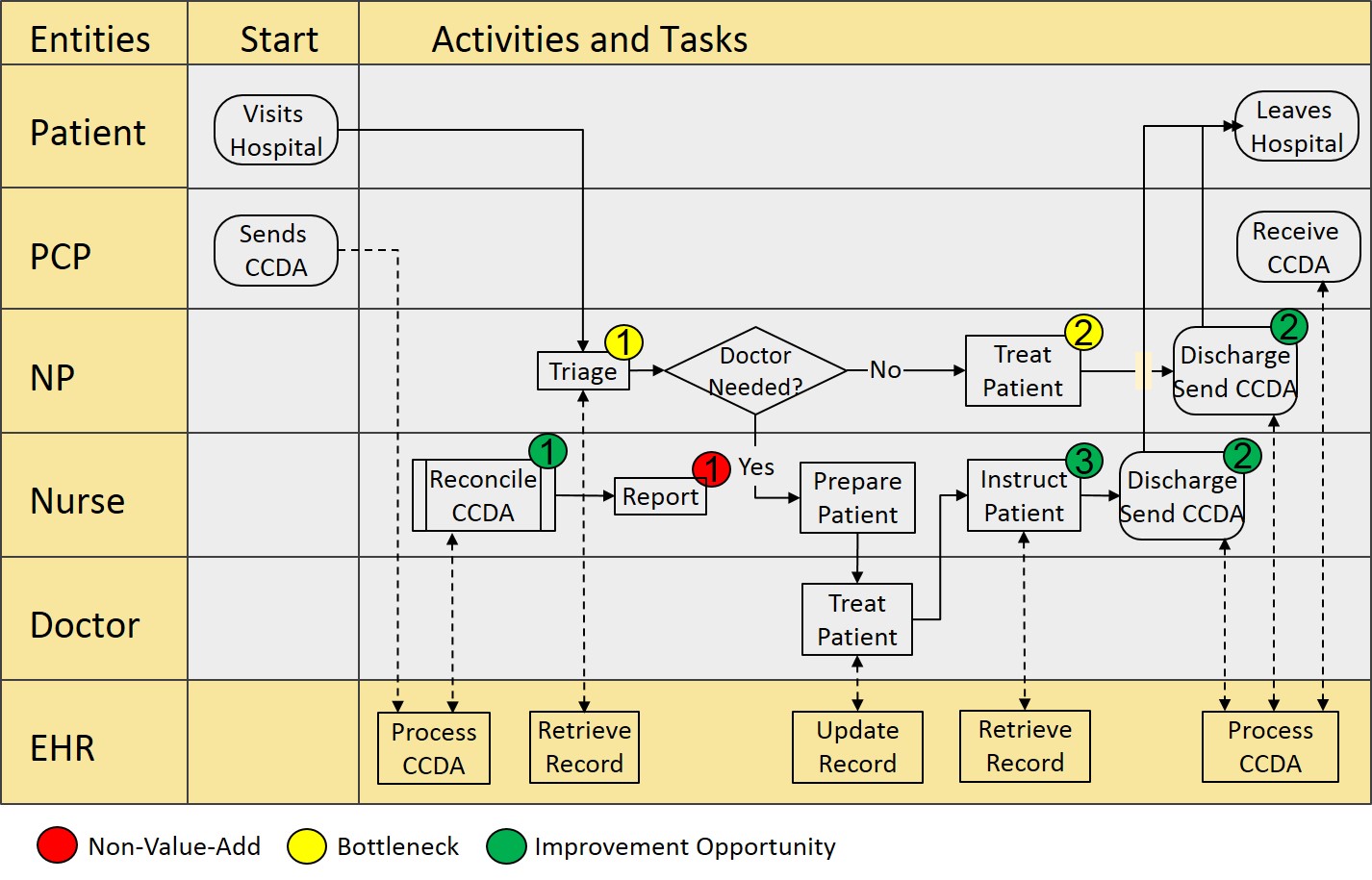

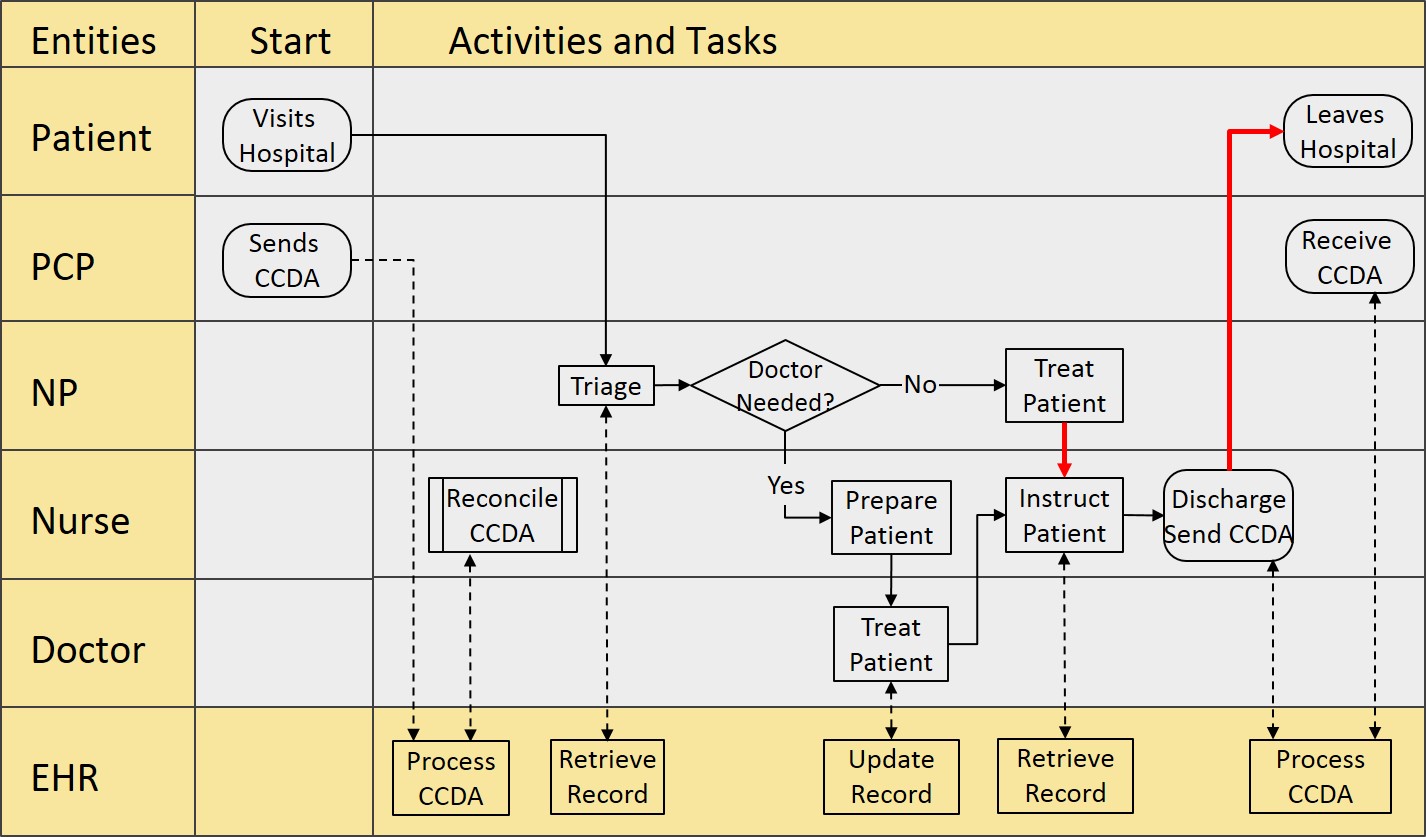

Process maps look like the graphic shown below. This example map shows a process with multiple clinicians involved in triaging, treating, instructing, and discharging a patient. Throughout this toolkit, this example will be used to illustrate the concepts explained.

A process map is basically a structured flow diagram. The added structure ensures greater clarity by avoiding the unwieldiness that often comes with traditional flow diagrams. This clarity will help in identifying process flaws and designing improvements.

In particular, the structure is conducive to establishing insight into who executes the various activities, the sequence of activities, and the hand-offs that occur to pass on the work between the people and systems that execute the process.

The main value of Process Mapping is the team discussion to uncover how the process works. This yields a great starting point for improvement discussions, but it is best to wait with improving the map until there is mutual understanding of how things currently work.

Select the "Process Mapping" tab to learn how to map a process.

Process Improvement

To establish success in Process Improvement, it is key to have a sound strategy that drives how the need for improvements will be identified, how the related process changes will be defined, and how success will be measured. This toolkit explains the strategy used in the Bottleneck Resolution Method (BRM).

It is important to not only know how the process works, but also how well it works. During Process Mapping, participants will discuss what they think works well. They will also disclose process flaws they are aware of, and through the discussion they will discover issues they weren't aware of.

Although this information is based on impressions and anecdotal evidence, these qualitative indicators provide a foundation to apply the BRM Process Improvement strategy. BRM can result in significant improvement even if the team hasn't quantitatively measured the actual process performance. It is in fact fairly common in service and administrative processes to have no or only limited metrics.

Select the "Process Improvement" tab to learn how the BRM strategy works.

Productivity Metrics

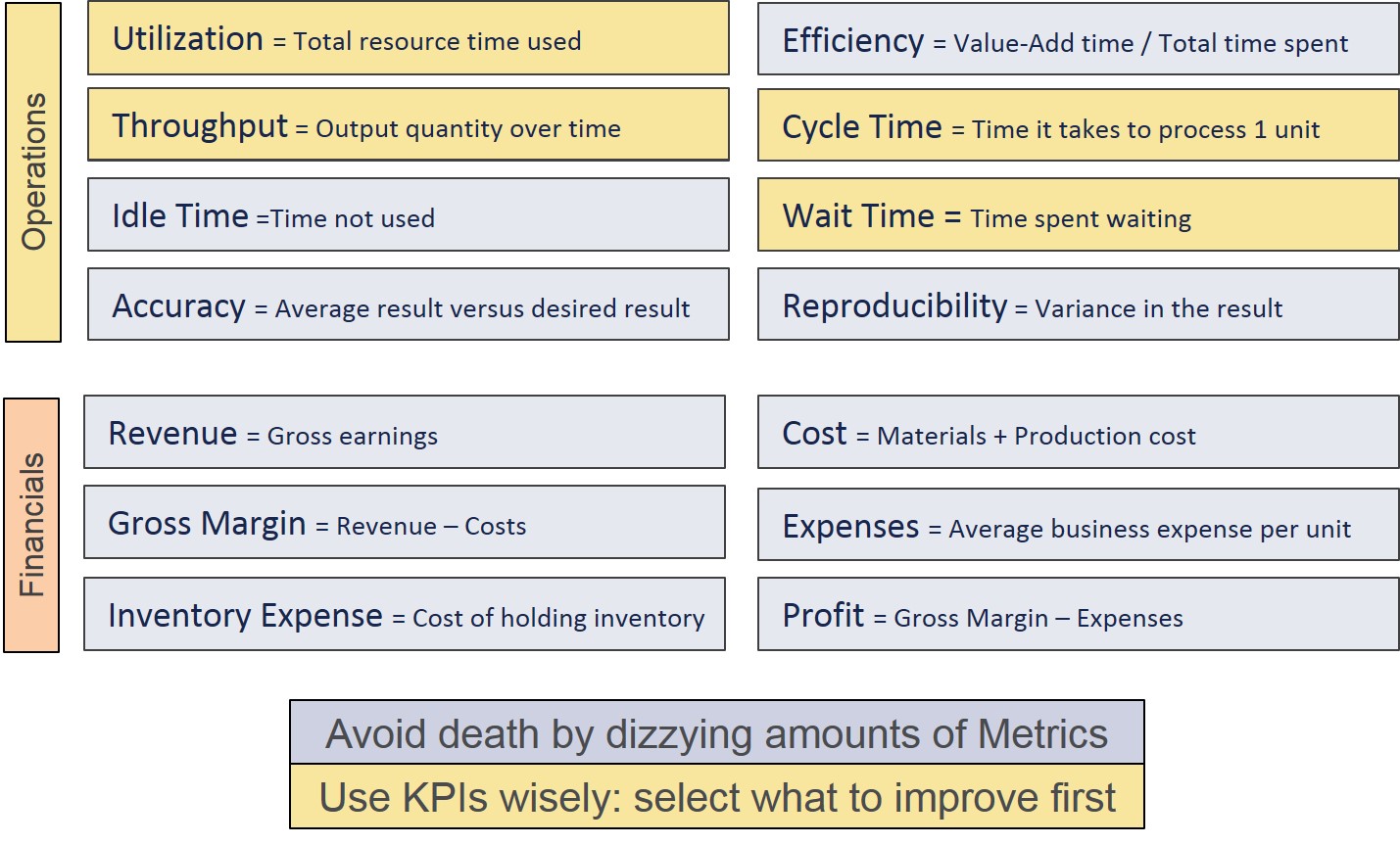

While qualitative impressions and anecdotal evidence provide a foundation for improvement, this may yield insufficient quantitative insight to refine the improvements. For instance, perceptions of how frequently certain issues happen is often biased. Small issues might seem relevant just because they occurred recently, and vice versa.

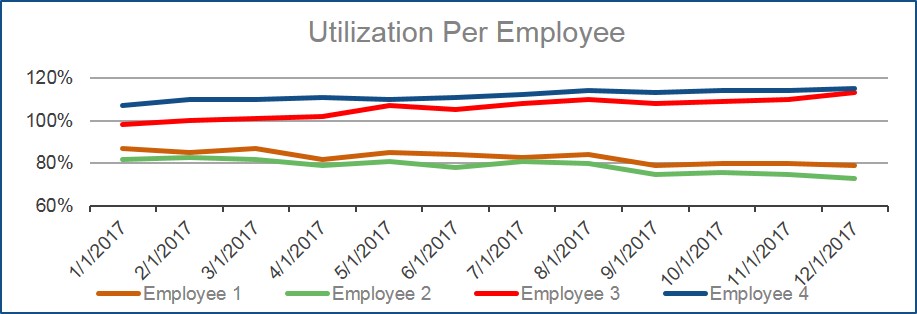

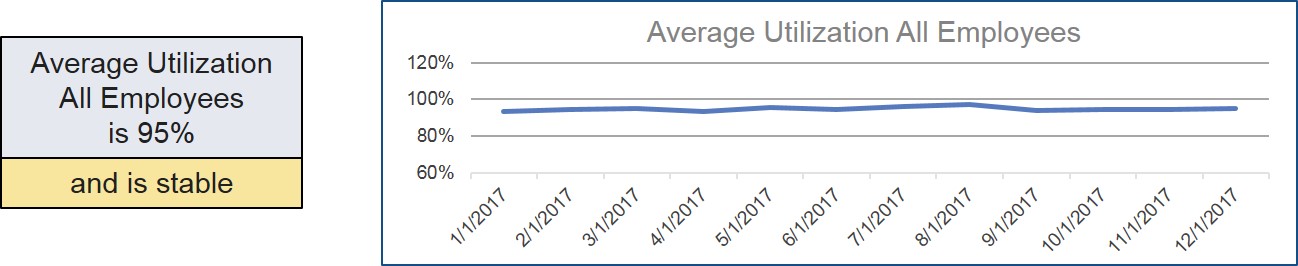

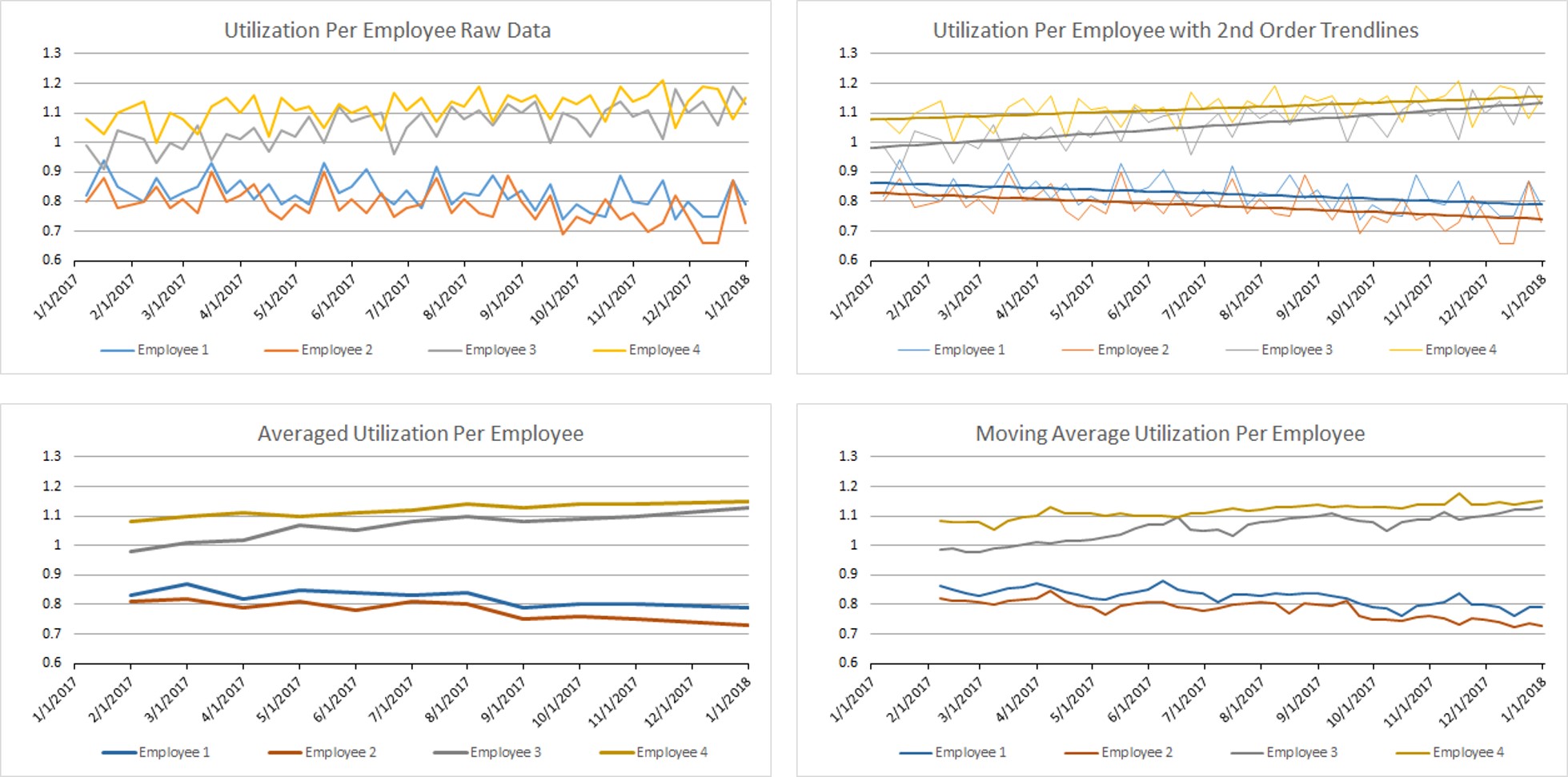

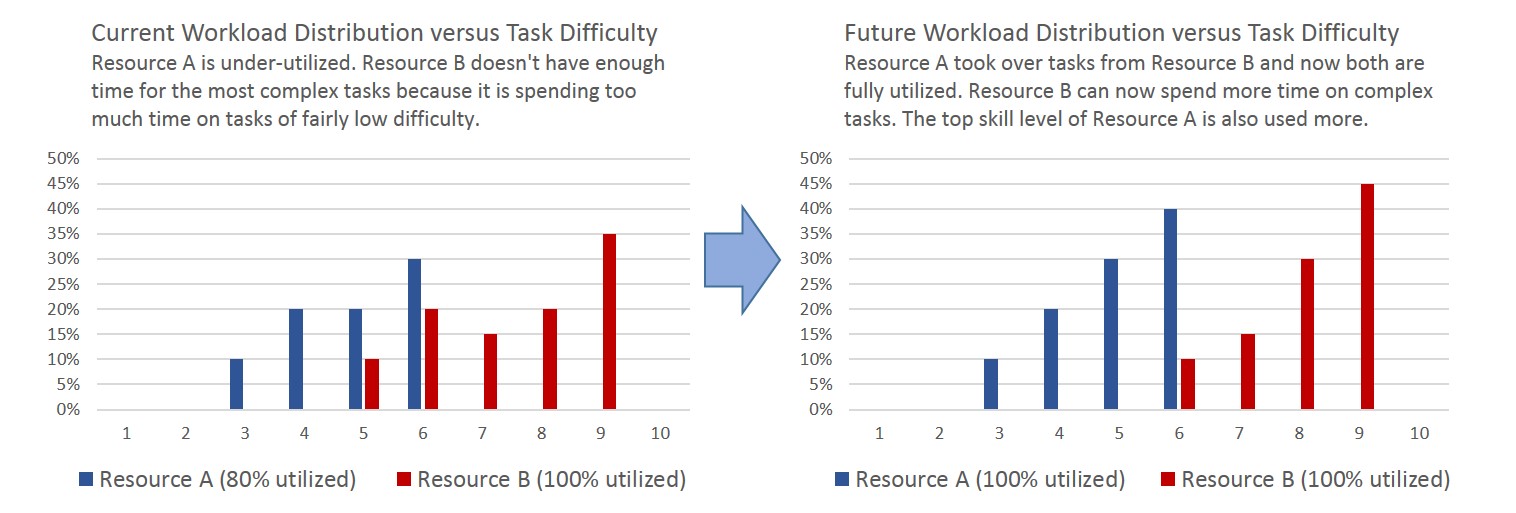

Advanced applications of BRM use Productivity Metrics to determine which improvements will be most effective. Metrics supplement qualitative impressions with quantitative insight. For instance, the employee utilization graph below shows that some employees are busier than others. This data would quantify a qualitative impression that this is the case.

Productivity Metrics measure process performance, such as time spent on activities, delay and wait times, and the quality of output. Such metrics can support decisions as to what to improve, and measure whether the improvements worked. As using metrics can get overwhelming, BRM proposes to keep the use of metrics simple and incremental.

Select the "Productivity Metrics" tab to learn more about how to use metrics effectively.

If using metrics isn't an option, still read the Productivity Metrics tab. Understanding the concepts behind metrics may offer insights that help in interpreting qualitative impressions and anecdotal evidence.

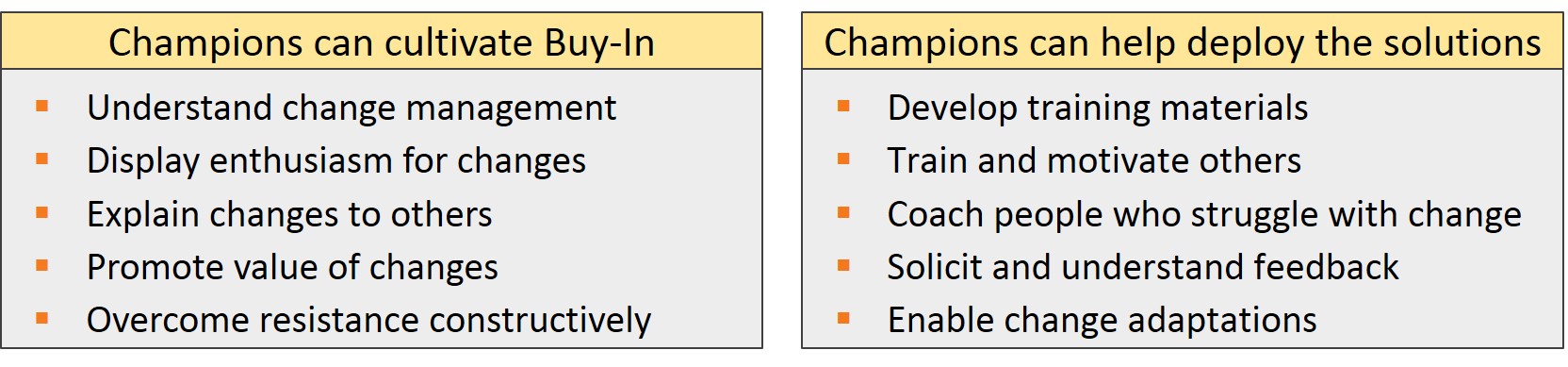

Facilitator

Process Improvement discussions can release emotions in the team where differing personalities and viewpoints come out and conflicts may arise. For a positive experience, it is therefore preferred to have a facilitator to guide the discussions. The facilitator can also teach the team about Process Mapping and Improvement.

Becoming a good facilitator requires a conducive mindset and some practice. This toolkit explains how facilitators can prepare themselves to implement the BRM method.

Select the "Facilitator" tab to learn more about how to prepare.

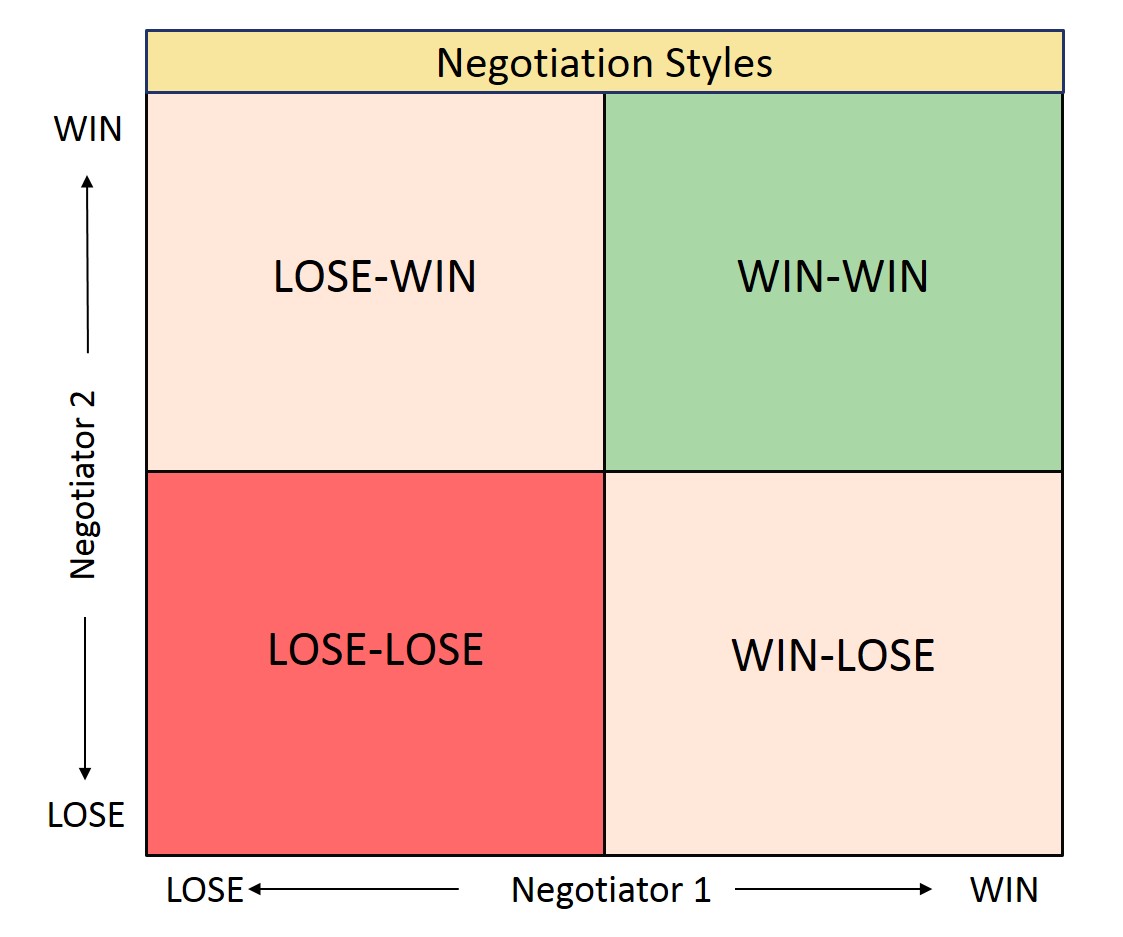

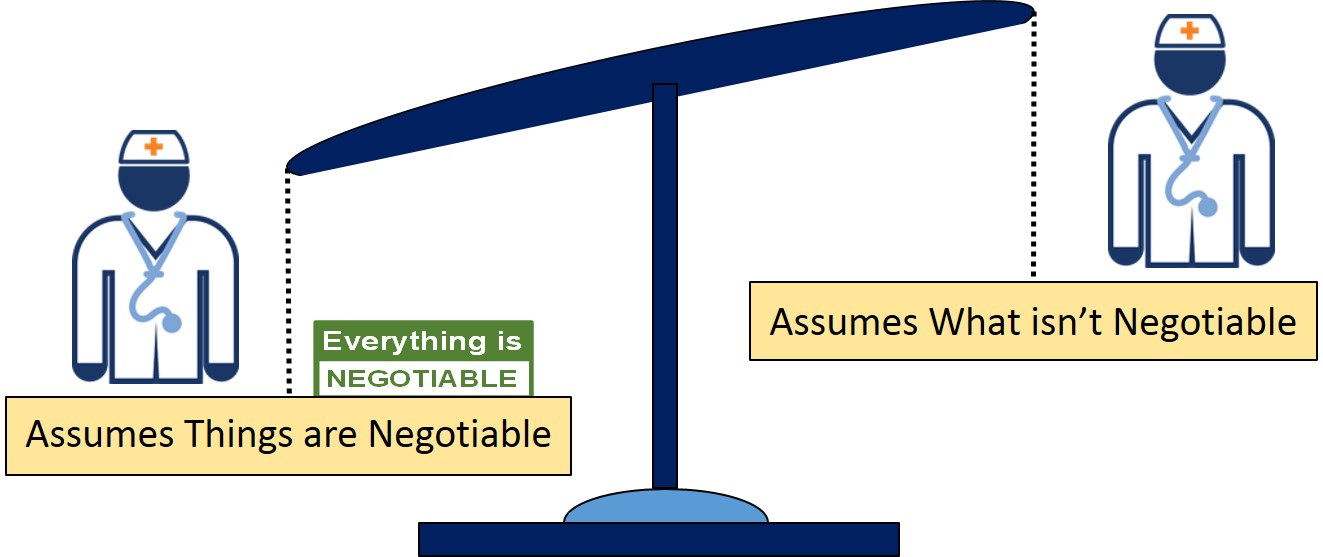

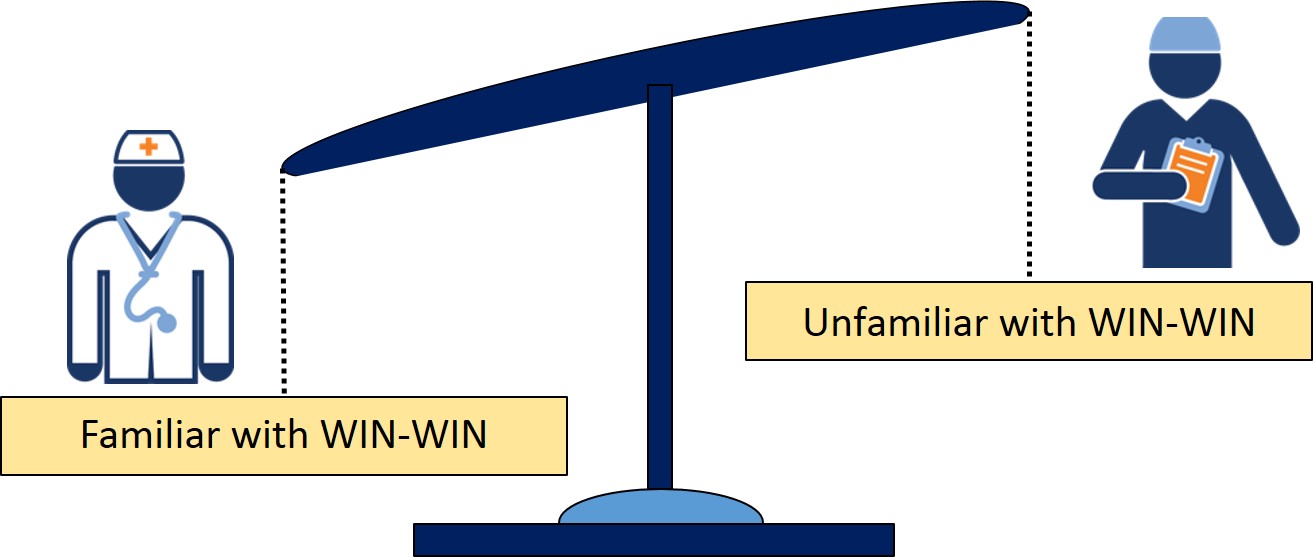

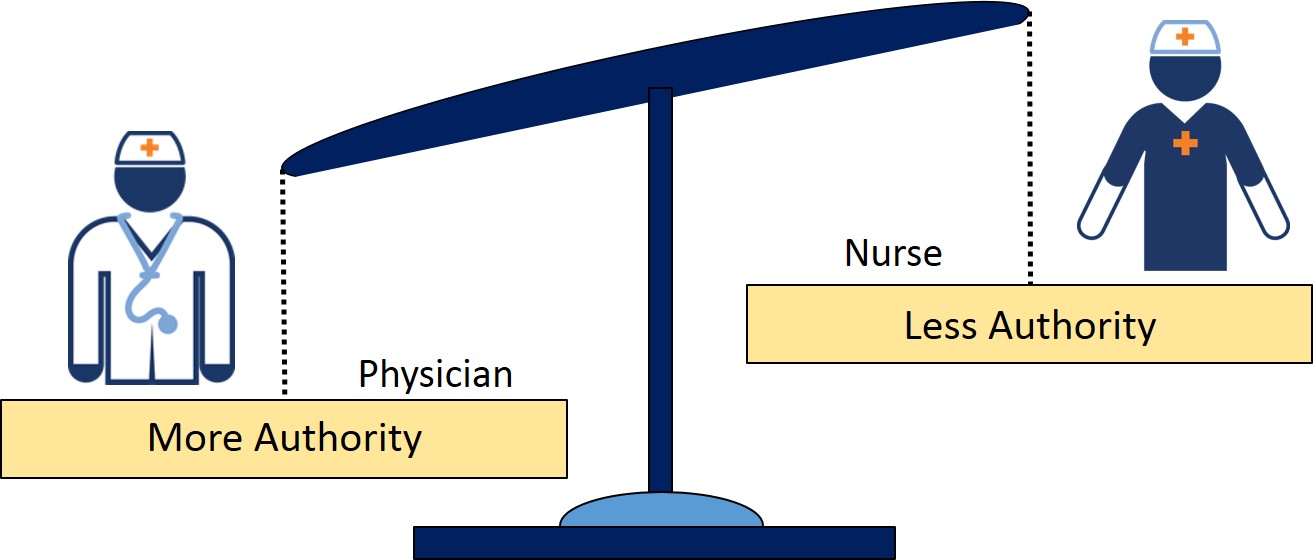

Negotiation

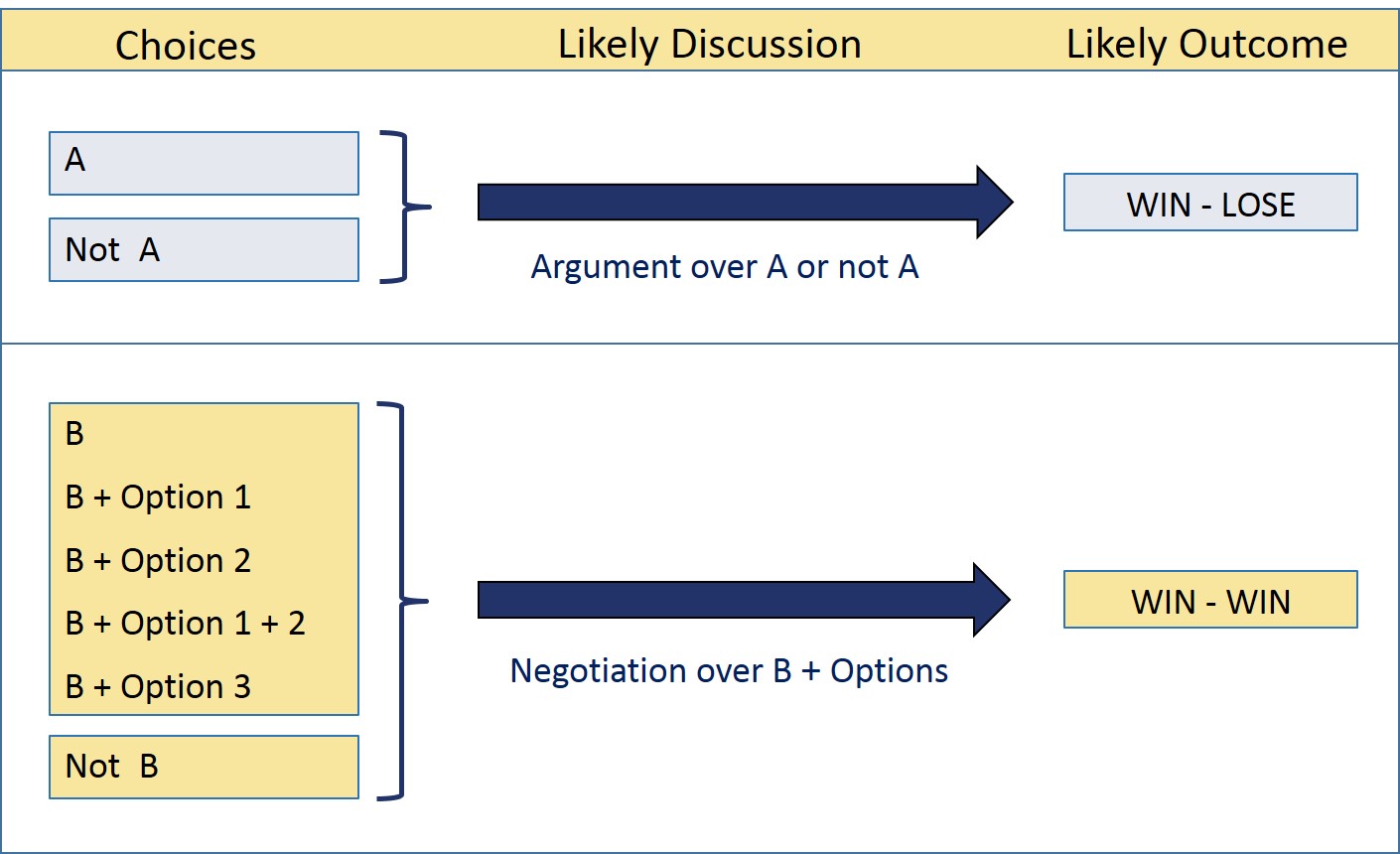

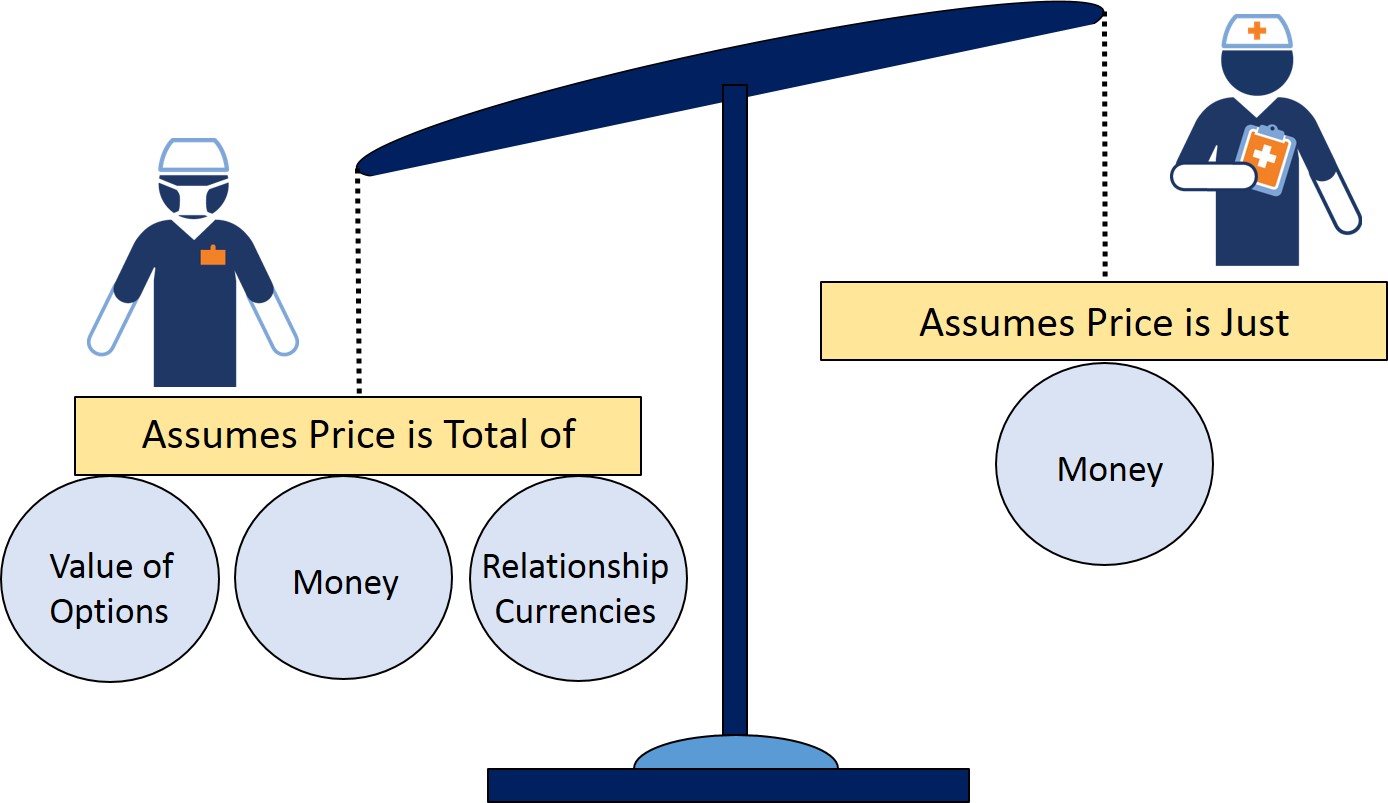

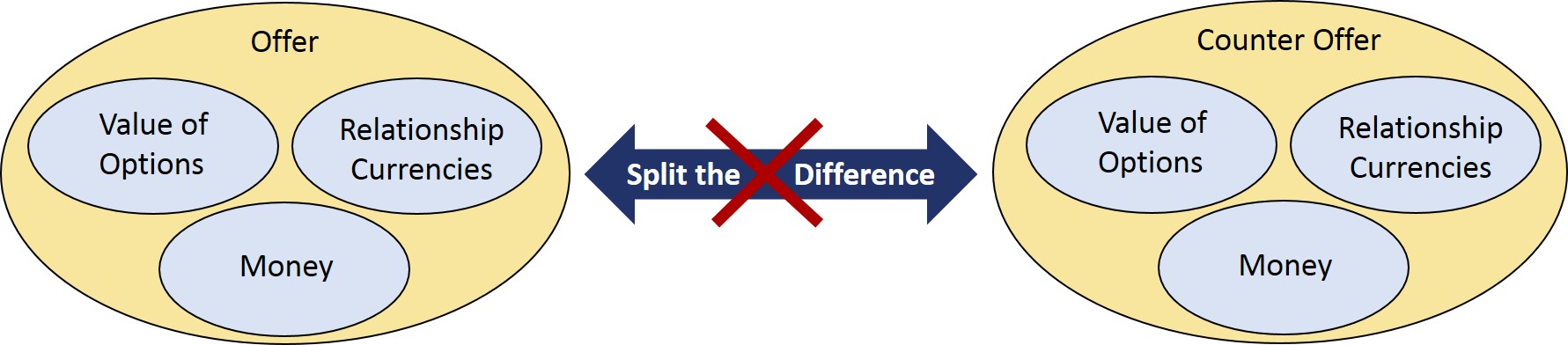

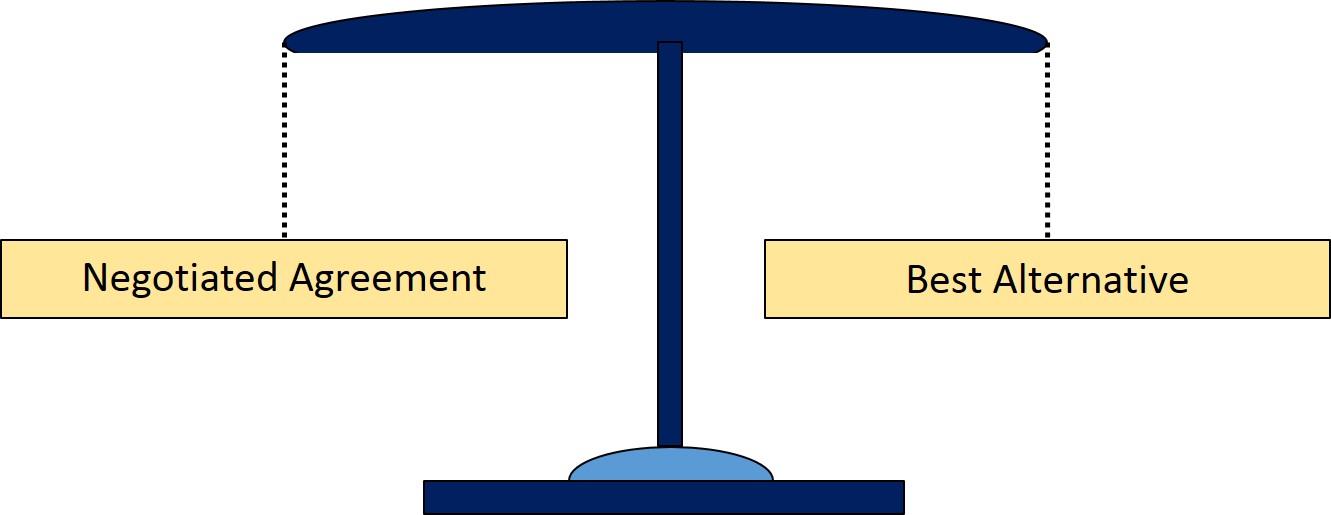

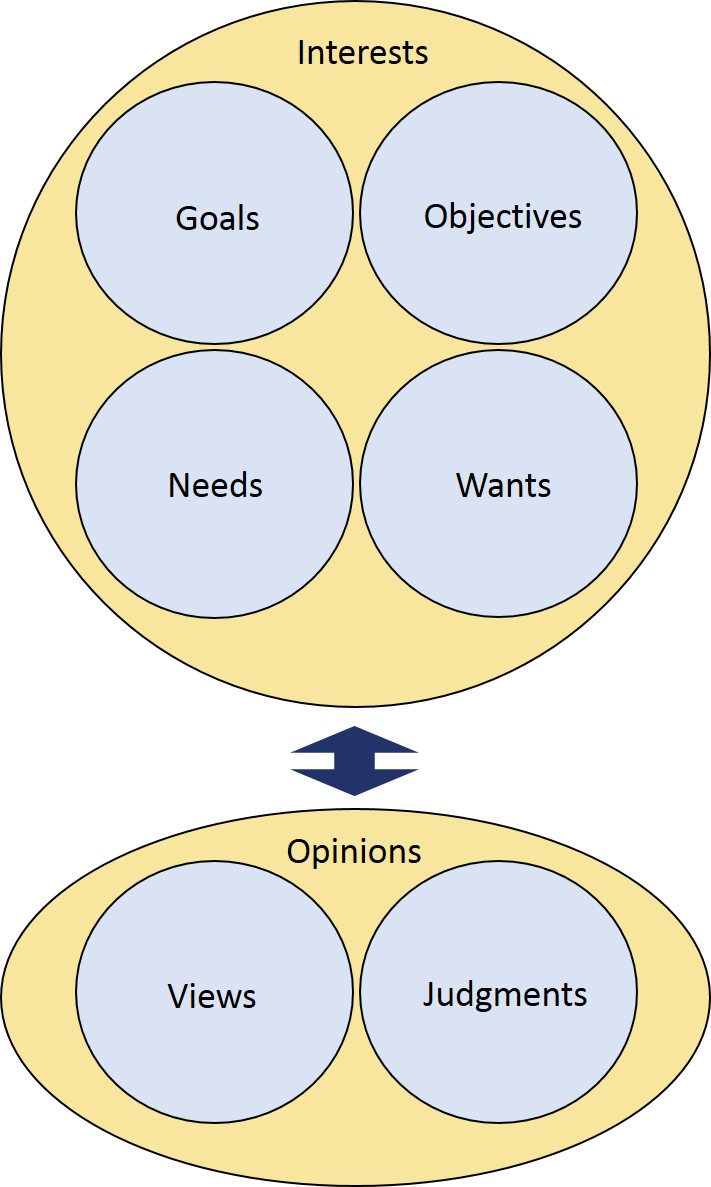

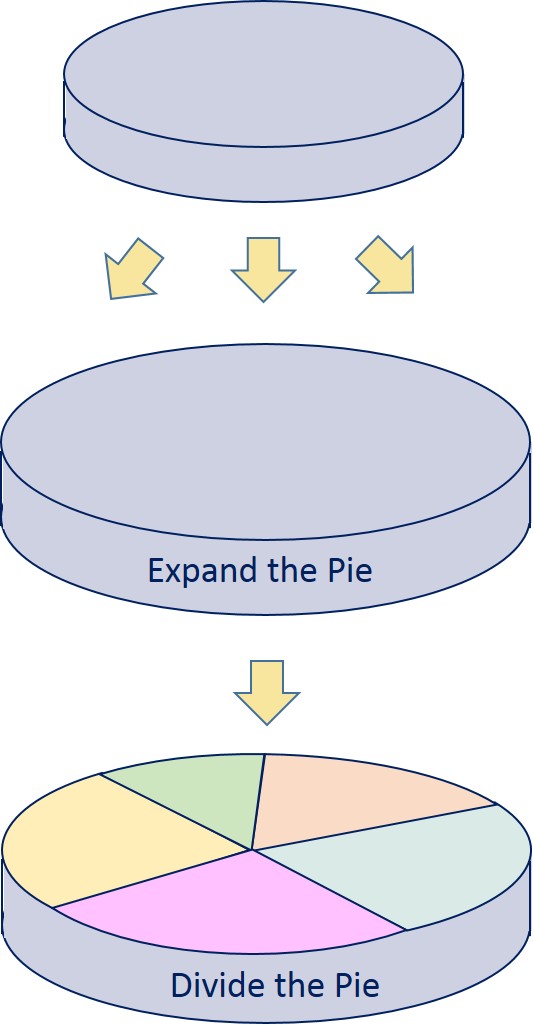

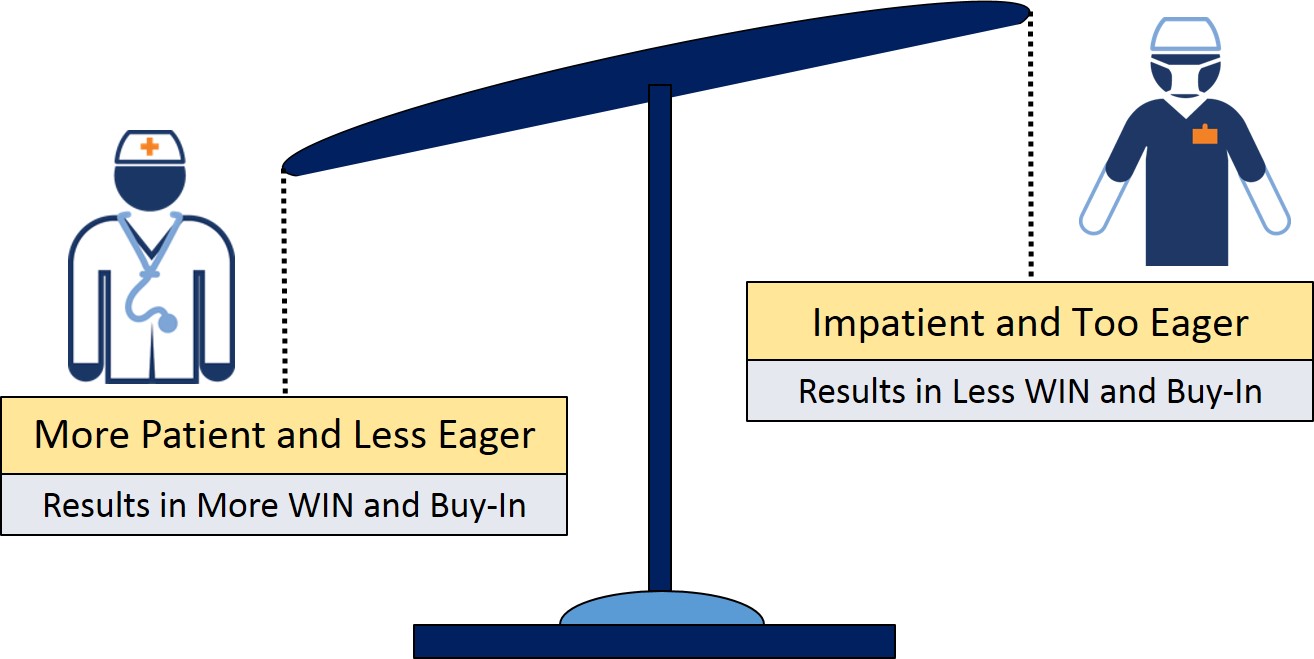

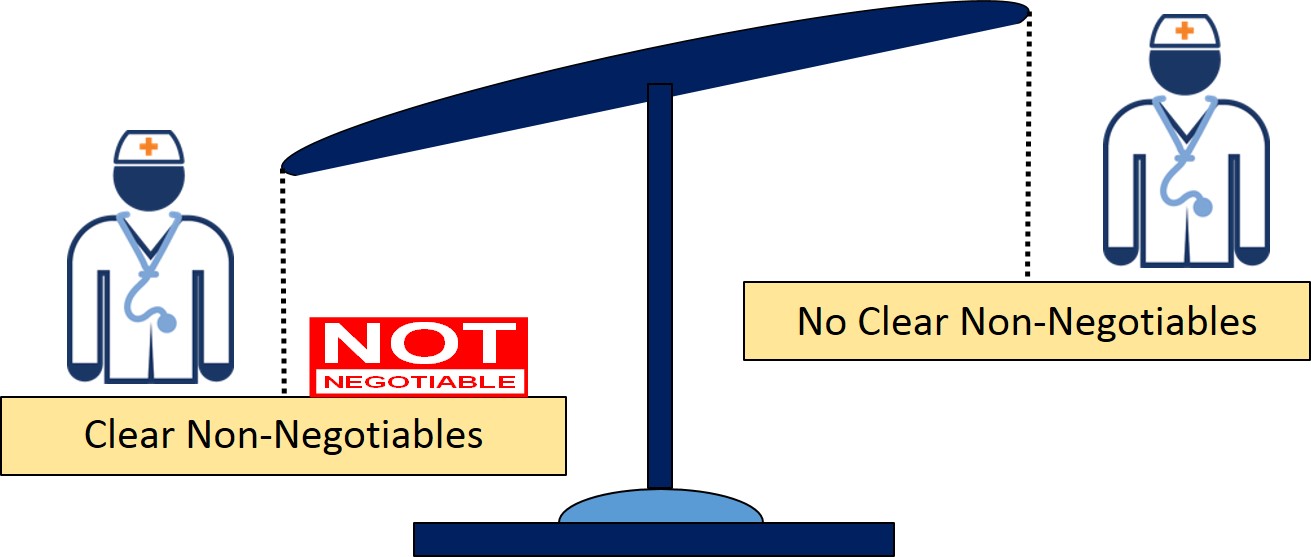

The perspectives of how a process should be improved will differ among the stakeholders. They will need to negotiate a solution that works for them and aligns with the business scope, goals, objectives, and budgets. BRM promotes the WIN-WIN Negotiation strategy as the preferred method to resolve the differences between the stakeholders.

The key component of this strategy is to define and negotiate alternative options for addressing the collective interests of the various stakeholders. For this purpose, the Process Improvement tab specifies a number of generic options that can be used to define and negotiate improvement proposals.

Select the "Negotiation" tab to learn more about WIN-WIN Negotiation.

Process Map Library

This toolkit includes process map and best practice examples to aid teams in generating Process Improvement ideas. These examples were created by participants of MeHI's Change Management and Process Improvement workshops organized by MeHI from 2018 to 2020.

Be careful not to impose the examples on your team. That will be counterproductive, as process maps and best practices created by one team rarely apply to other teams. The main value of BRM comes from the discussions with your team. Don't undermine this by imposing other people's processes.

Select the "Process Map Library" tab to review the example process maps and best practices.

Process Selection

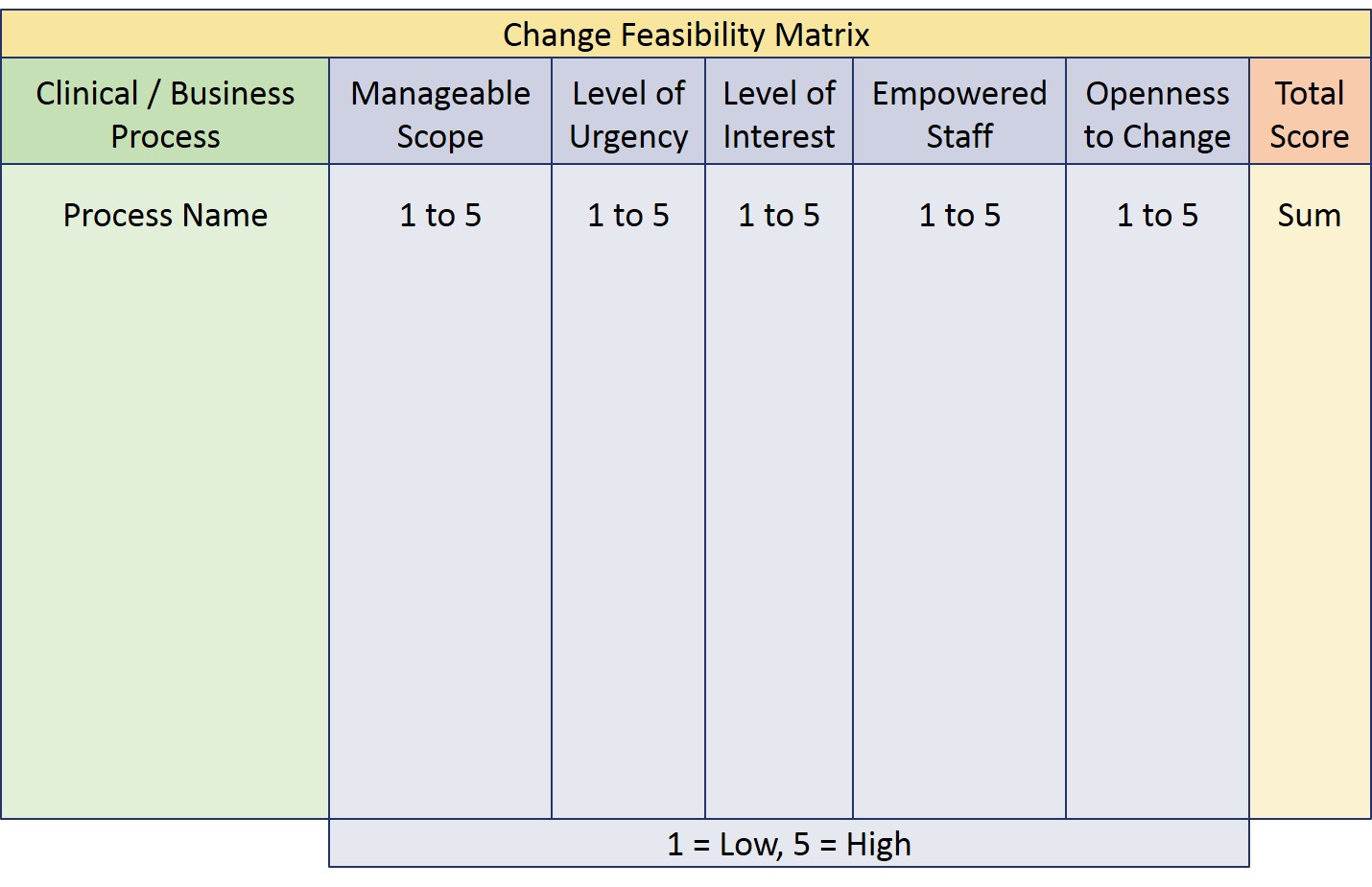

To get off to a good start with BRM Process Improvement, begin with a process that has strong change feasibility. This is a process where the change effort is relatively low, and the likelihood of success is fairly high. Manageable effort and success will motivate the team to continue with improving other processes.

Good candidates are smaller processes that are manageable in scope, have a manager who empowers the staff, and are executed by a team that is open to change. To be successful, everyone involved should have a sense of urgency and an interest to improve the process. These characteristics make it more likely for teams to perceive change as feasible and valuable, and to get on board.

The next sections discuss Process Selection tools that will help select processes that match these characteristics.

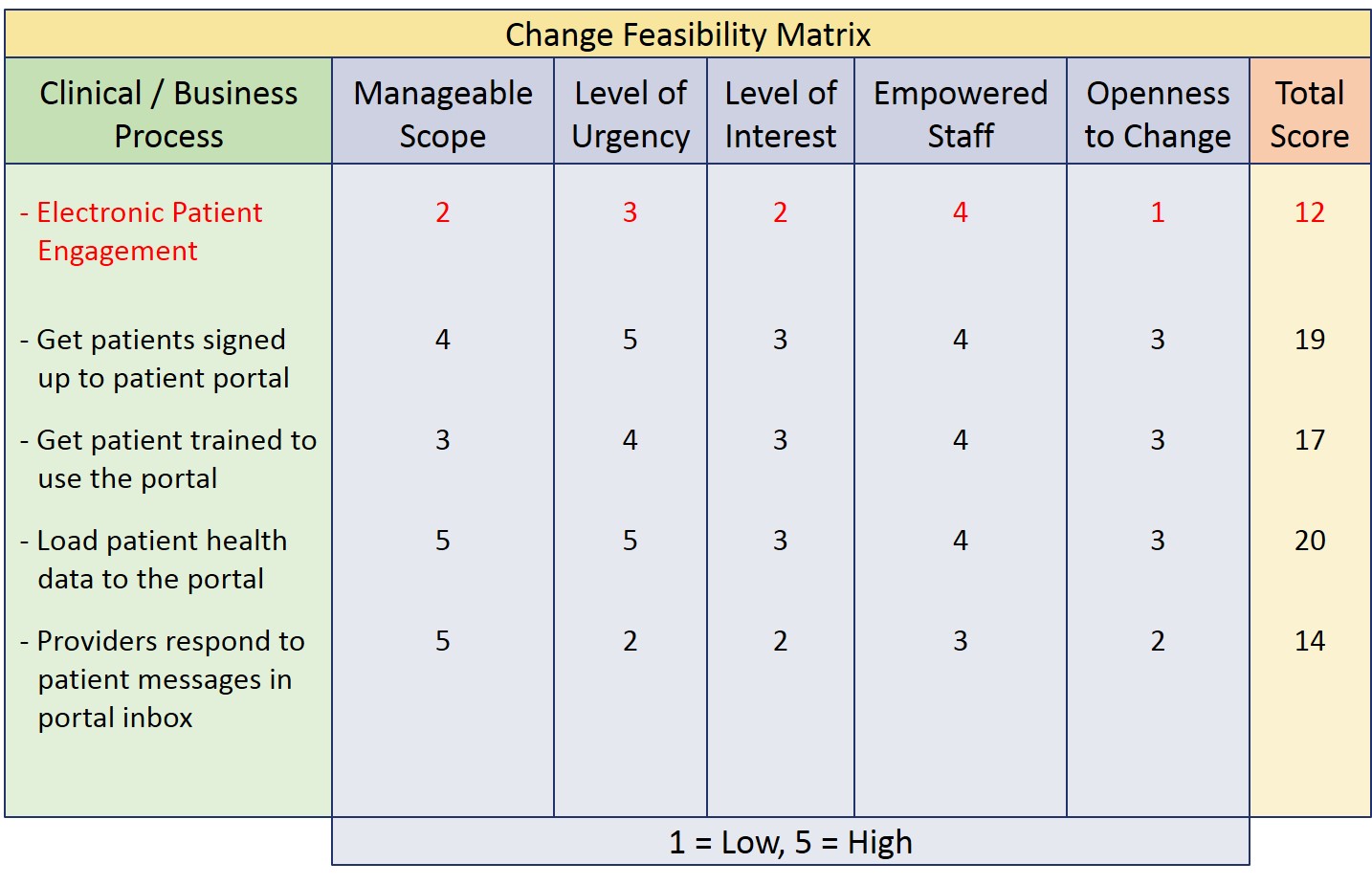

Change Feasibility Matrix

The Change Feasibility Matrix shown below can be used to rate existing processes based on the feasibility characteristics discussed above. Work with the team to:

- Brainstorm which processes the team may want to improve, and list these processes in the green column.

- Discuss how to score the change feasibility drivers of each process, and list these scores in the 5 blue columns.

- Sum the scores and list the total in the pink column.

From a feasibility perspective, the process with the highest total score is in principle the best candidate to improve first.

- If all processes have a low total score, break some processes up into sub-processes that may have a higher score.

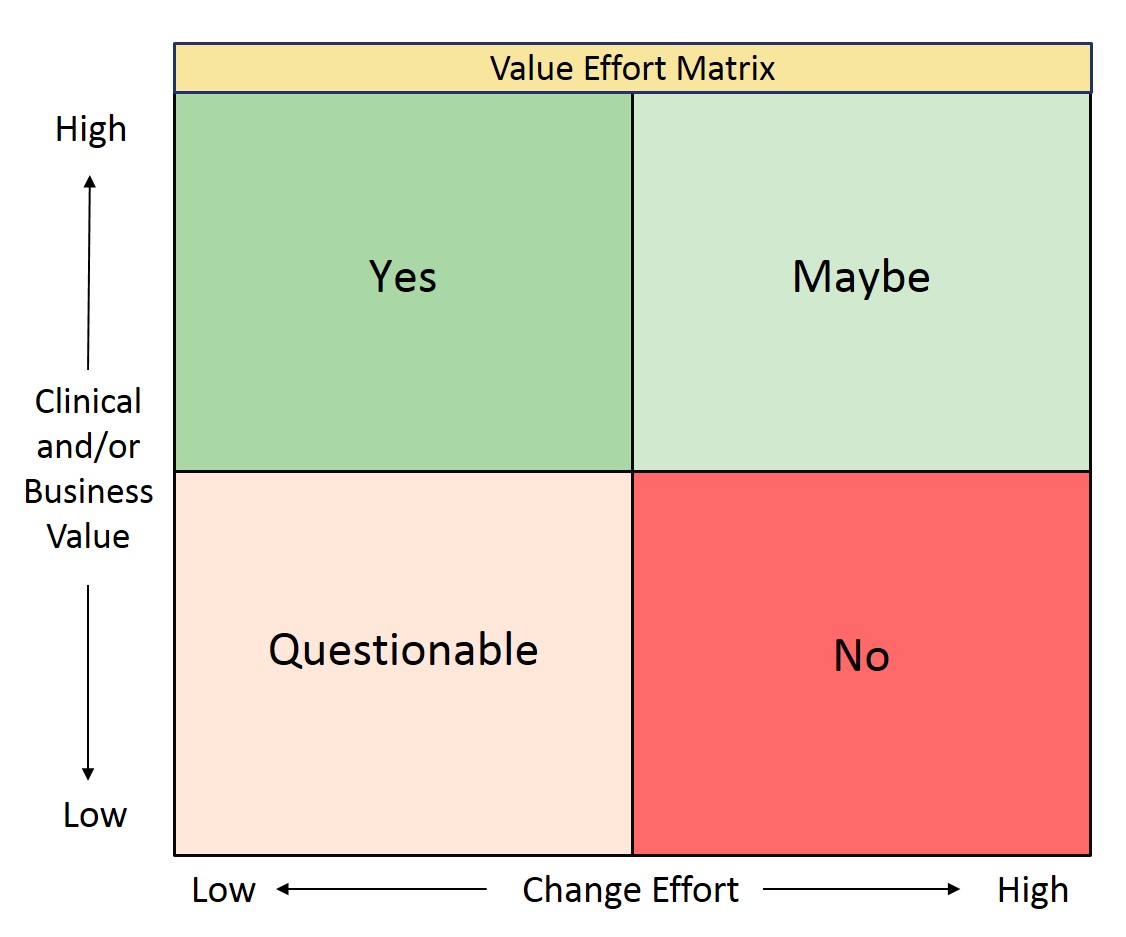

Value Effort Matrix

A high change feasibility doesn't necessarily mean that Process Improvement will add substantial value. Just because change is easy, doesn't make it valuable.

The Value Effort Matrix shown below can be used to further refine the Process Selection. The purpose is to evaluate the business value of improvement versus the change effort. Use the matrix to refine which process to improve first:

- Place the top candidates identified with the Change Feasibility Matrix above into the quadrants of the Value Effort Matrix.

- The value is higher if the improvement has a larger impact on the process outputs, customer satisfaction, or business financials. For instance, if it improves the clinical outcomes.

- The effort is inversely related to the total score in the Change Feasibility Matrix, meaning low feasibility correlates to more effort. For instance, effort is higher for complex processes with a large scope.

Once the processes are placed in the Value Effort Matrix, the matrix can be used to select the order in which to improve the processes:

- Processes in the dark green quadrant are the best candidates to improve first. The low effort and high value make success realistic and the impact significant. It is the low hanging fruit.

- Processes in the light green quadrant are the best candidates to improve next. The effort is higher, but it still comes with significant value. Be careful though not to start with processes that require a lot of effort.

- Processes in the pink quadrant can be improved third in line, but consider carefully before doing so. While the effort is low, the value is also low. Only improve processes where the value is at least reasonable.

- Improving processes in the red quadrant tends to be too complex and not impactful. This leads to wasted effort that might be better applied to further refine the other processes.

Example

The graphics below show an example of Process Selection. In this case, the team brainstormed an Electronic Patient Engagement (EPE) process. They first completed the Change Feasibility Matrix.

Originally, EPE was evaluated as a single topic, but the team realized that this was too complex. The total score was low. The scope wasn't manageable, there was little interest, and the openness to change was low.

In the next step, the team broke EPE into four smaller sub-processes of more manageable scope. When they realized a process can be broken into more realistic chunks, the interest and openness to change increased.

Three of the four sub-processes received a reasonable total feasibility score. The fourth sub-process still had a fairly low score, but this process was perceived as non-critical to initial success.

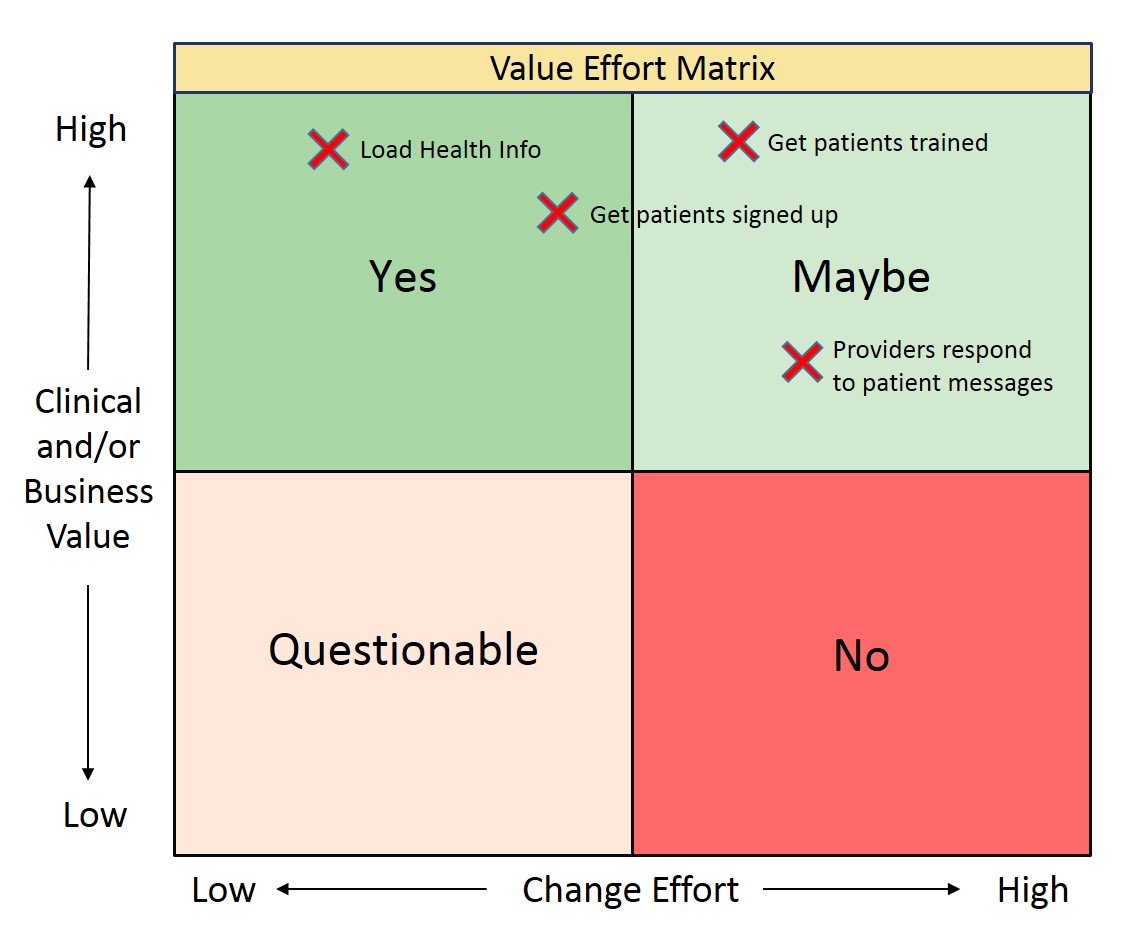

Subsequently, the team completed the Value Effort Matrix by placing the four sub-processes into the matrix.

Based on the matrix, the team decided to first map the sub-process to get patients signed up, and then the sub-process to get patients trained to use the portal. The team discussed that both processes should focus on patients who could benefit the most from the portal, such as patients with chronic conditions.

While the sub-process to load health information was seen to have the highest value/effort ratio, the clinically oriented team declined to map this process. They considered it an IT process that could be automated by IT.

Subsequently, two process maps were created, which are included in the Process Map Library of this toolkit. The maps were actually created by two separate teams that both came to the same conclusion in their Process Selection. To review the maps, click here.

Process Mapping

Continue the BRM Process Improvement by organizing a Process Mapping session with the team to chart the selected process. Process maps are conducive to establishing insight into the process activities, the sequence of the activities, who executes the activities, and the hand-offs between the people and systems involved. This tab discusses how Process Mapping works.

The main goal of Process Mapping is to get everyone on one page to establish mutual understanding of the current process. It is typical for participants to experience Aha moments when they realize the process doesn't quite work the way they thought it worked. These moments often correspond to improvement opportunities, so make sure to take notes of such discrepancies.

However, wait until the process map has been completed before defining improvements, because that yields a clean starting point to begin the discussion on how to effectively improve the process.

Canvas

The process will be mapped on a canvas. Use a large whiteboard, or a series of sheets of easel paper taped to the wall as the canvas. During the discussion, write down the identified process activities on sticky notes and place them on the canvas. Draw arrows to connect the notes to show the execution order and hand-offs. The sections below provide detailed instructions on how to create the map.

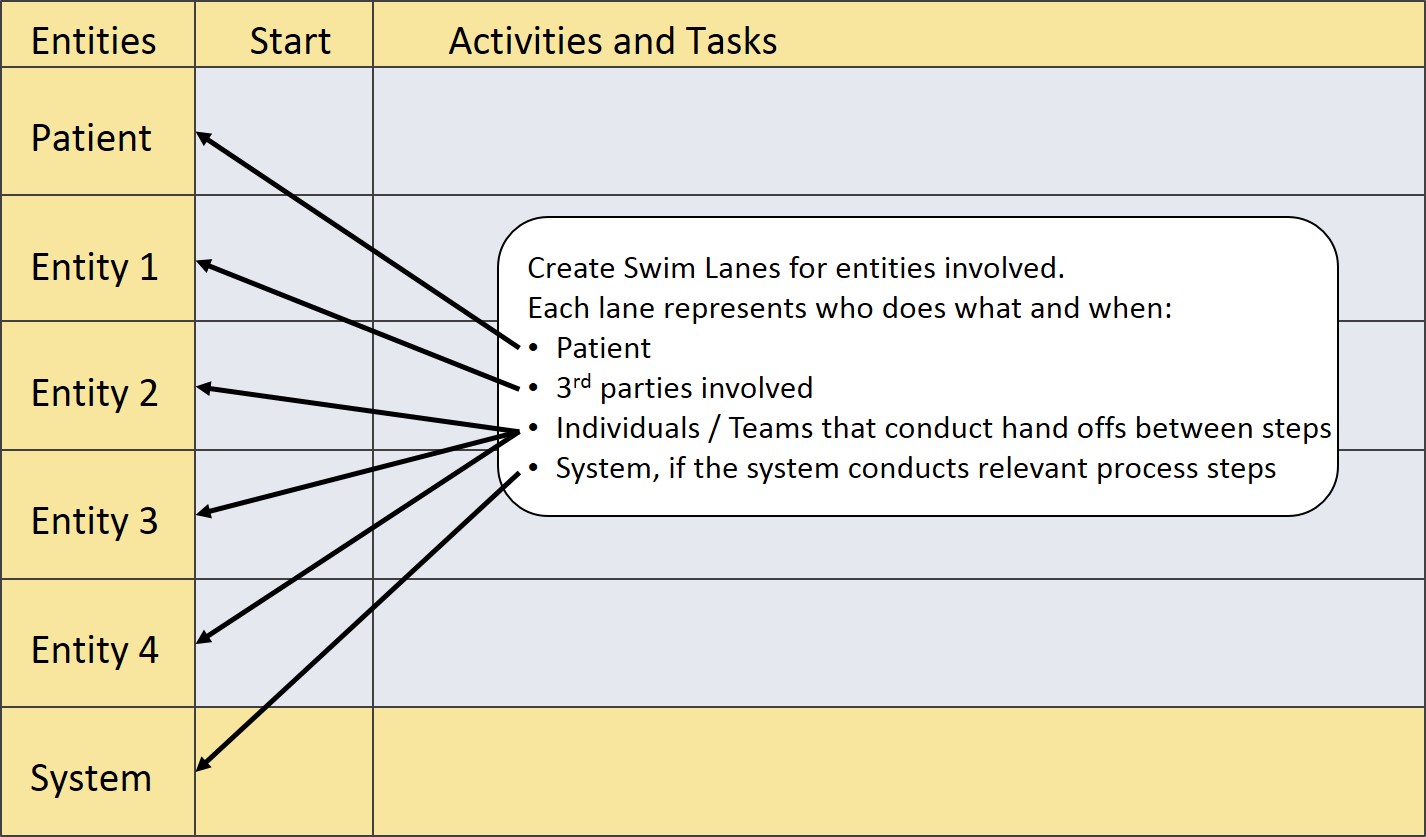

Swim Lanes

Draw swim lanes on the canvas. A swim lane represents an entity with a specific role in the process. Separating the entities is a key enhancement to traditional flow diagrams, where the entities are embedded within the flow. The swim lanes create a much clearer picture of who does what.

Use the swim lanes to map the activities and tasks that are executed by each entity. Each lane must correspond either to a single person, or a team of people who all execute exactly the same role. If there are differences in roles, use separate swim lanes. For instance, in a patient care process:

- the physicians, nurses, administrators, and anyone else affecting the care of a patient should be assigned separate swim lanes.

- the patients are engaged in the process, so the patients need their own swim lane.

- the care providers may interact with computer systems, such as an EHR. Because the systems fill a role, systems must also be assigned a swim lane.

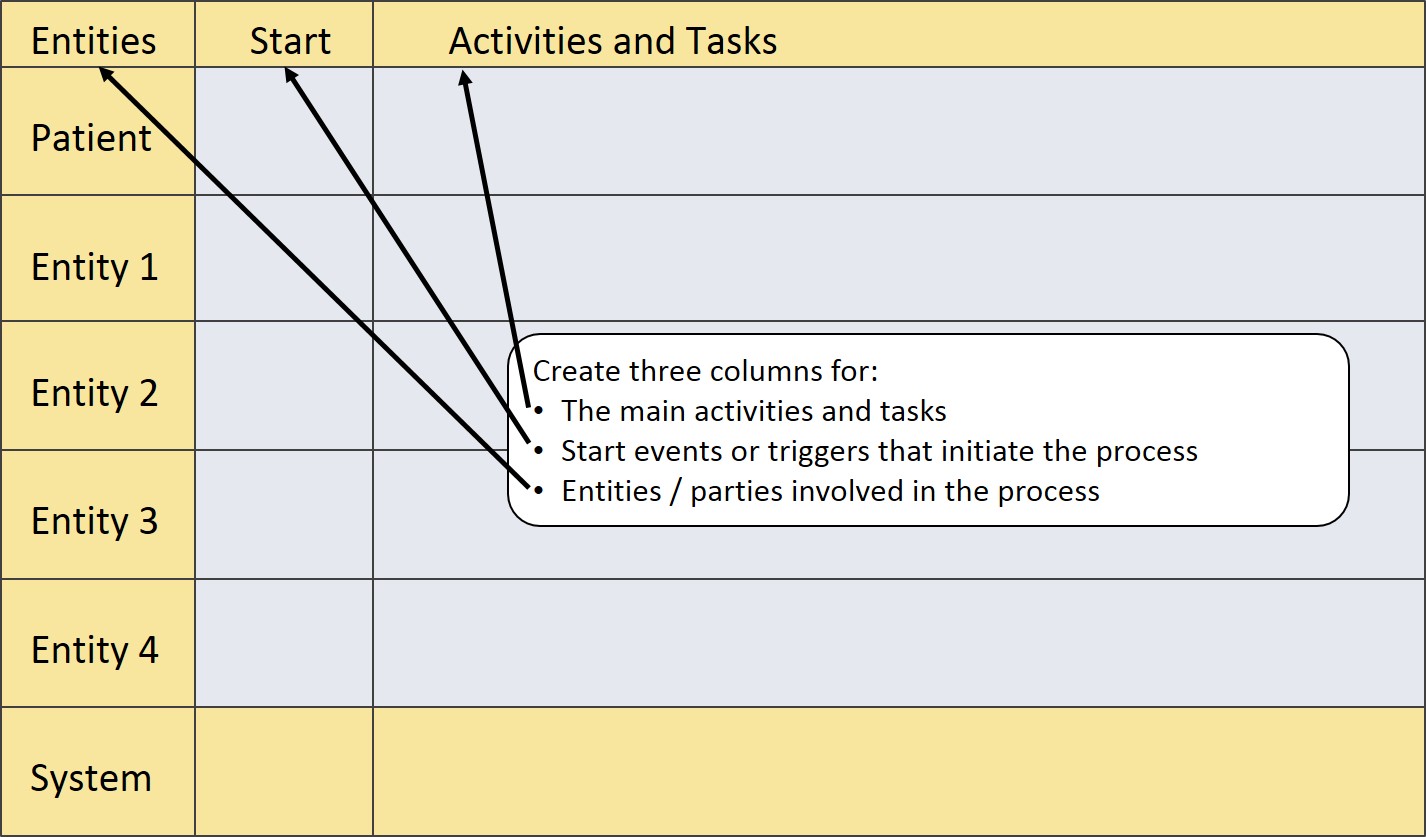

Entity and Activity Columns

Draw three columns on the canvas. Use the first column to list a title or name for each entity involved, the second to highlight the activity that starts the process, and the third to map the activities, tasks and decisions executed by the entities.

Process Mapping Symbols

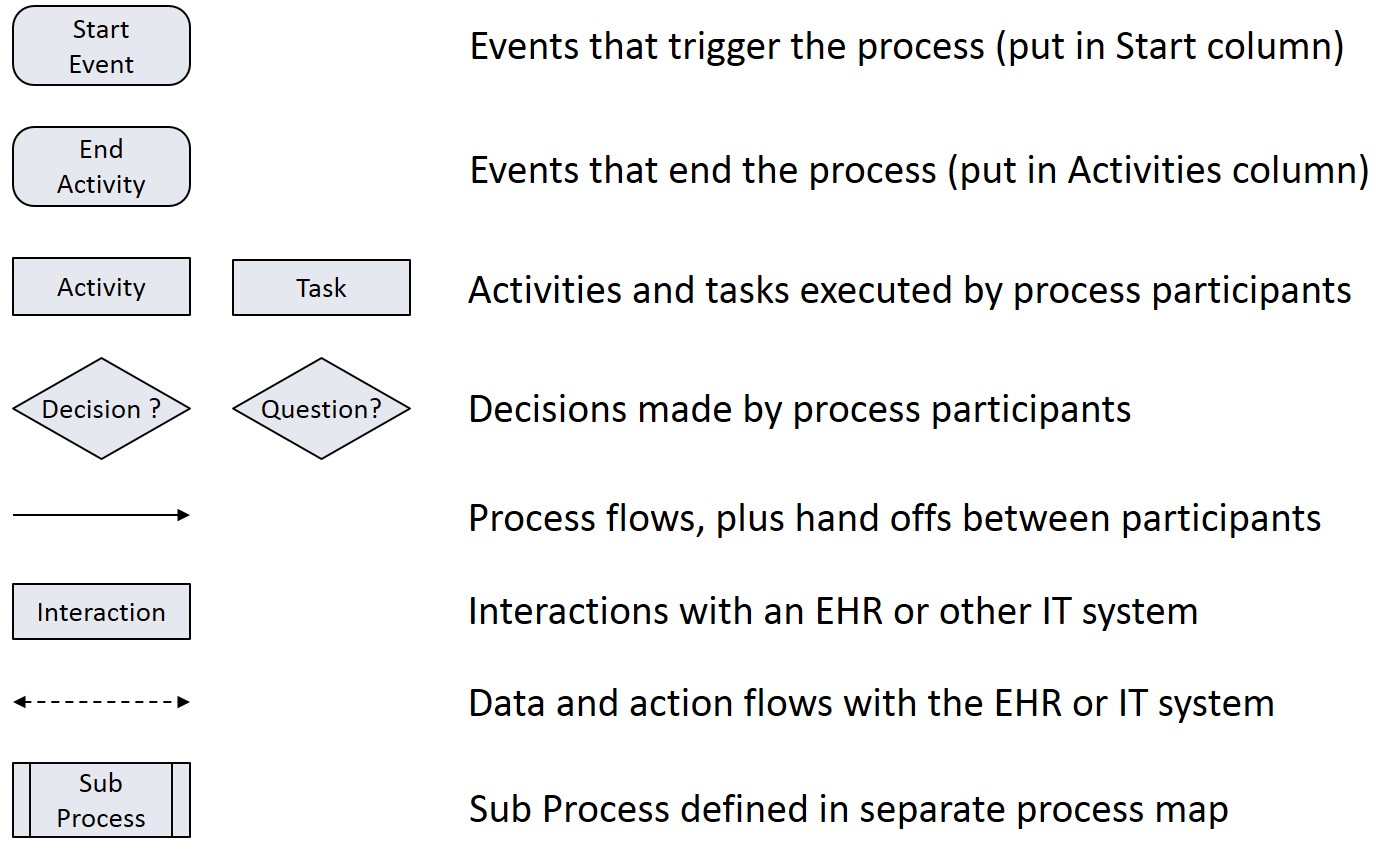

During the mapping session, use sticky notes to represent the activities and place each note in a swim lane based on the entity that executes the activity. Use markers to draw arrows to represent the process flow.

After the session, use a flowchart program to recreate the map electronically so you can share the map with the team. For instance, MS Visio can be used to document a process map as a "Cross-Functional Flowchart", which supports the swim lanes.

Flowchart programs use various symbols to layout the process flow. It isn't quite practical to use these symbols during a live Process Mapping session. The following sections describe how to use the symbols in a flowchart program, and how to use the sticky notes during a live session to match the electronic layout.

Activity and Task Symbols

In an electronic process map, use rounded boxes to show the triggers that start the process and any activities that end the process. Use rectangular boxes to show all other activities and tasks, and diamond shaped boxes for questions and decisions. Use solid arrows to show the order of activity execution, and the hand-offs between the entities.

During a live session, use sticky notes for all boxes, and use square notes tilted by 45 degrees as diamonds. Place only start triggers in the Start column. Place all other notes in the Activities and Tasks column. Draw arrows with a marker, but not until the team is sure of the execution order. Teams typically keep moving notes around, and add notes, during the discovery of how the process works.

System Interaction Symbols

In an electronic process map, use rectangular boxes to show activities completed by a system, e.g. an EHR. Draw the arrows between people and system activities as dashed lines, because interactions with a system usually represent data flows rather than activity flows. Except, if a system clearly automates part of the process, then draw the hand-offs between the system and people as solid arrows.

During a live session, use sticky notes for the boxes, and draw the arrows with a marker after the process flow is established. Most of these arrows should be dashed lines, unless there is automation involved.

Sub-Process Symbol

A process may be too complex to map out as a single process. In this case, it is better to map parts of the process as sub-processes. That keeps the main process map simpler and cleaner. In an electronic process map, use a special symbol to highlight the embedded sub-processes in the map. It looks like an activity box, but has two extra side bars.

During a live session, use sticky notes for the boxes and draw bars on the sides. When part of the process side tracks a mapping session with too much detail, it can be appropriate to suggest introducing a sub-process to park the detailed discussion until later.

Layout of a Process Map

Following the above description, process maps typically look like the example shown below.

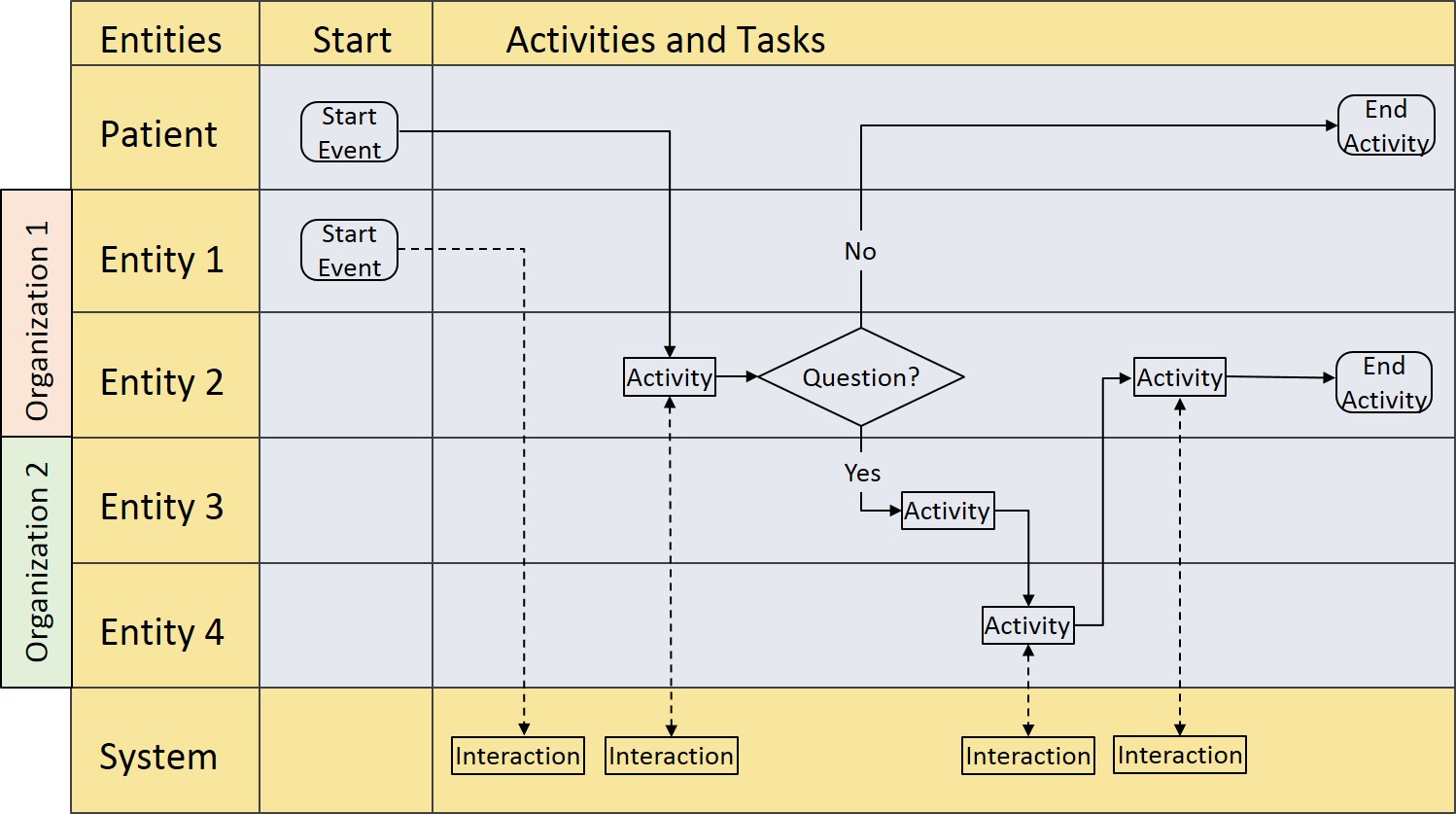

Processes across Multiple Teams or Organizations

Processes may run across multiple teams or organizations. In this case an extra column can be added in front of the map to clearly show the team or organization that each entity works for.

Process Mapping Rules

When making a process map, follow the key rules listed in the table below. These rules were designed to make the maps clear and efficient. There can be exceptions to these rules, but make sure that the map remains clear to the participants.

| Category | Rule | Description |

|---|---|---|

|

Sequence |

Create Timeline |

Treat the swim lanes as a timeline, so the process map shows the progression of the activities. |

|

Avoid Loops |

Minimize looping back from boxes on the right to the left. This appears to show rework, but confuses the timeline. Show rework as new activities down to the right. This also reflects that rework tends to differ from original work. | |

| Activities and Tasks |

Use Action Statements | Use clear action statements of what is being done in the activity or task. Action statements start with a verb. |

| Make Entities Unique | Action and task statements should never list the name of an entity. If this seems necessary, add more swim lanes. | |

| Use at least 1 Solid Incoming Arrow | There must be at least one solid incoming arrow. Use of multiple incoming arrows is allowed to reflect multiple paths leading to an activity or task, but maps tend to be clearer if this is avoided. | |

| Use 0 or 1 Dashed Incoming Arrow | Additionally, there can be one dashed incoming arrow coming from a system activity. This shows that data is retrieved from the system during the activity or task. | |

| Use only 1 Solid Outgoing Arrow | There should typically be one solid outgoing arrow. Adding more arrows makes it ambiguous what happens next. If this is necessary, add an activity that states why the process splits into multiple paths. | |

| Use 0 or 1 Dashed Outgoing Arrow | In addition, there can be a dashed outgoing arrow that leads to a system activity. This shows that the activity or task results in data being added to the system. | |

| Decisions and Questions |

Use Discrete Decisions or Questions | Use decision or question statements with discrete and unique answers, such as Yes/No. This ensures clarity in where the process flows next. |

| Make Entities Unique | Decisions or questions should never list the name of an entity. If this seems necessary, add more swim lanes. | |

| Use at least 1 Solid Incoming Arrow | There must be at least one solid incoming arrow. Use of multiple incoming arrows is allowed to reflect multiple paths leading to a decision or question, but maps tend to be clearer if this is avoided. | |

| Use at least 2 Solid Outgoing Arrows | There must be at least two solid outgoing arrows to reflect the possible decisions or answers. The decisions or answers must be written on or above the arrows. | |

| Use 0 Dashed In or Outgoing Arrows | There can be no dashed arrow going in or out of a decision or question. Add a leading or trailing activity or task to reflect the exchange with the system. |

Process Map Illustration - Part 1

The process map below illustrates how Process Mapping can be used to map out how a process works. The story behind this map is as follows:

- A Patient is referred by their Primary Care Physician (PCP) to visit a Doctor at a hospital.

- The PCP sends a C-CDA to the hospital.

- The C-CDA is received by the hospital's EHR and then reconciled in the system by a Nurse.

- When done, the Nurse creates a reconciliation report.

- When the Patient comes in, a Nurse Practitioner (NP) triages the Patient.

- The NP decides whether the Doctor needs to see the Patient:

If Yes:

- The Nurse will prepare the Patient to be seen by the Doctor.

- The Doctor will treat the Patient and then send him/her back to the Nurse.

- The Nurse will give instructions to the Patient and discharge the Patient.

- The Nurse will send a return C-CDA to the PCP.

If No:

- The NP will treat the Patient.

- The NP will then discharge the Patient.

- The NP will send a return C-CDA to the PCP.

- The Patient leaves the hospital.

- The PCP receives the C-CDA from the hospital.

Improvement

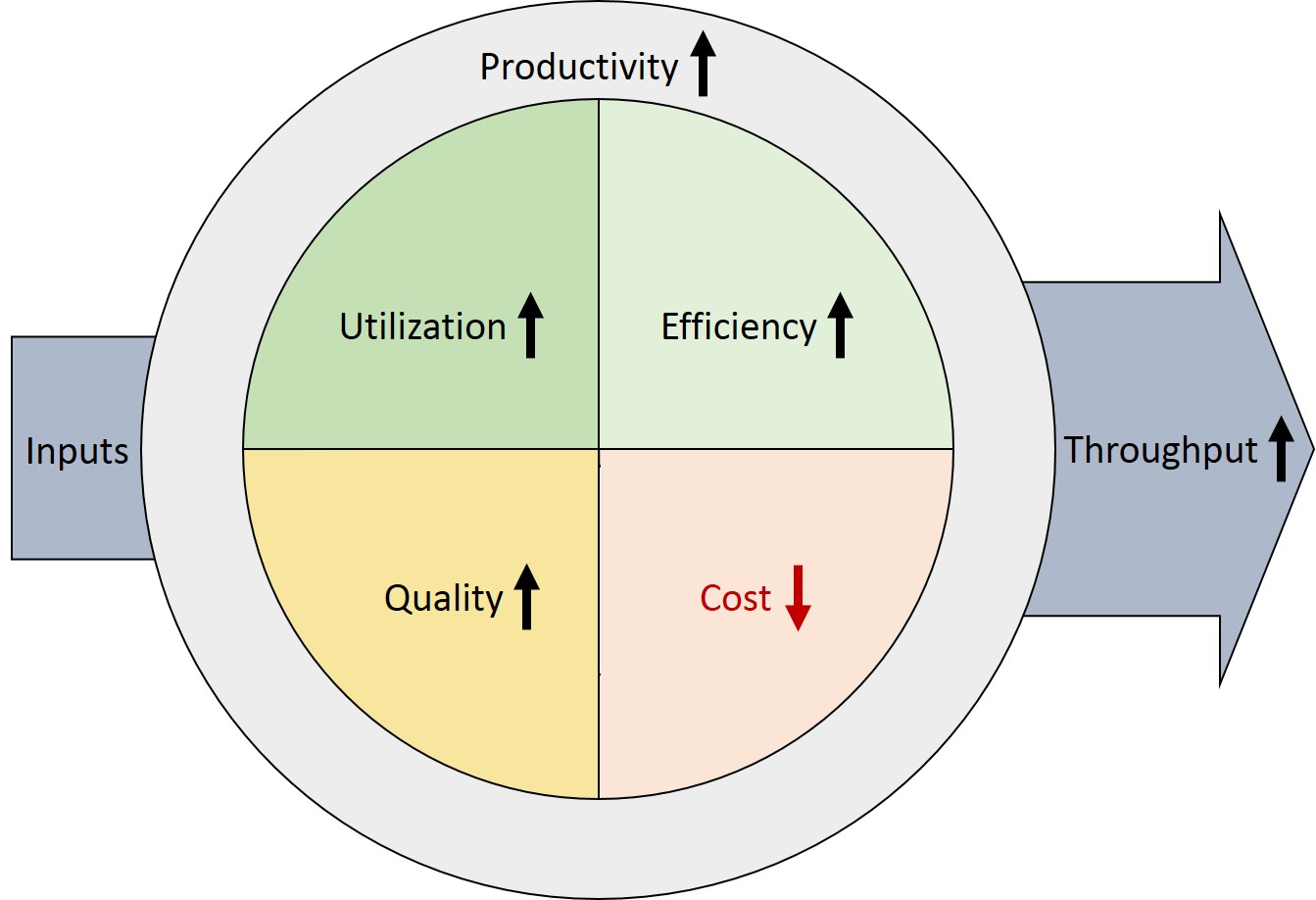

Once the current process has been mapped, the next step in the Bottleneck Resolution Method (BRM) is to improve the productivity of the process. Productivity is defined by the quantity and quality of the process outputs versus the cost of producing those outputs. The goal is to increase the profitability and impact of the process by increasing the productivity.

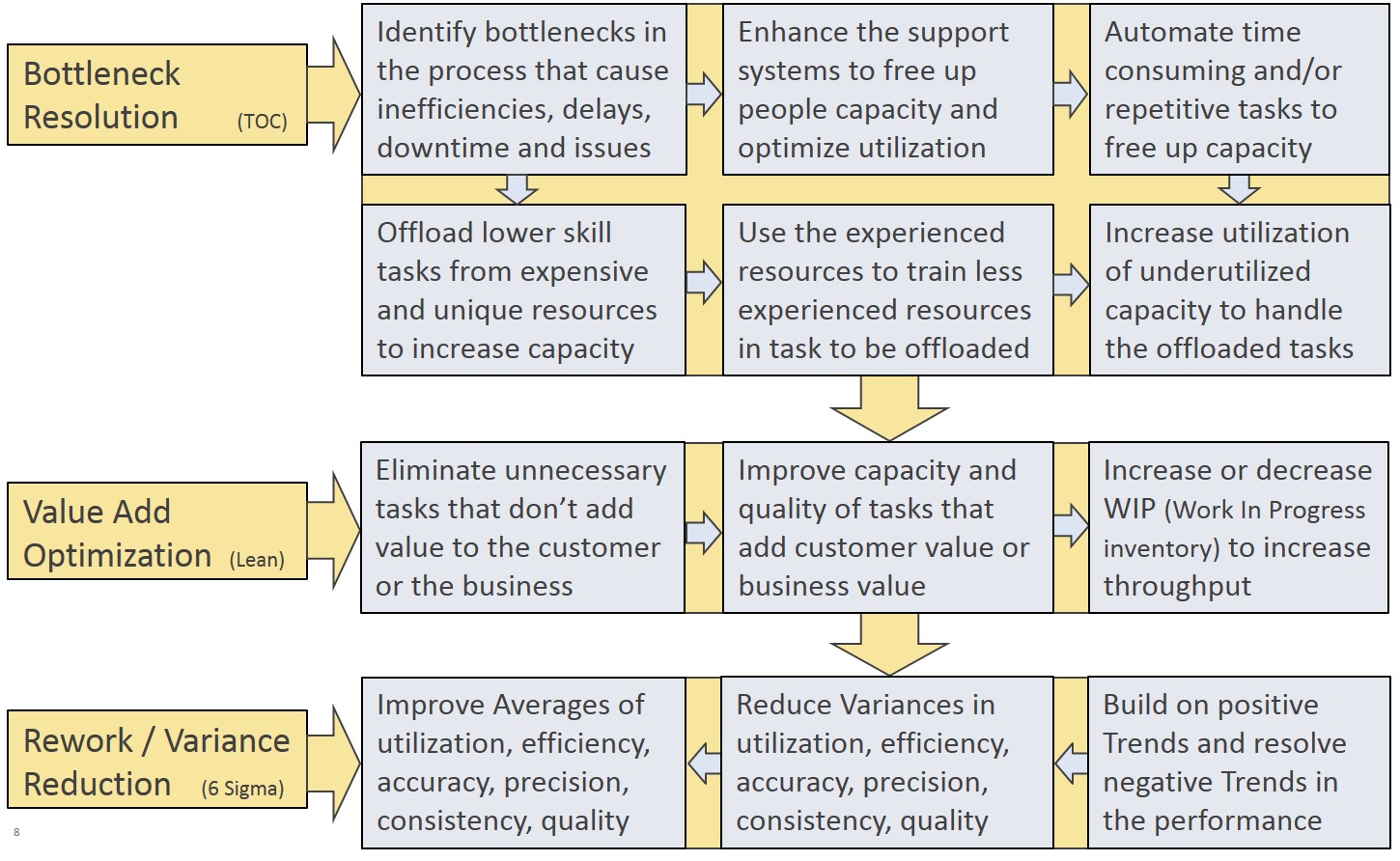

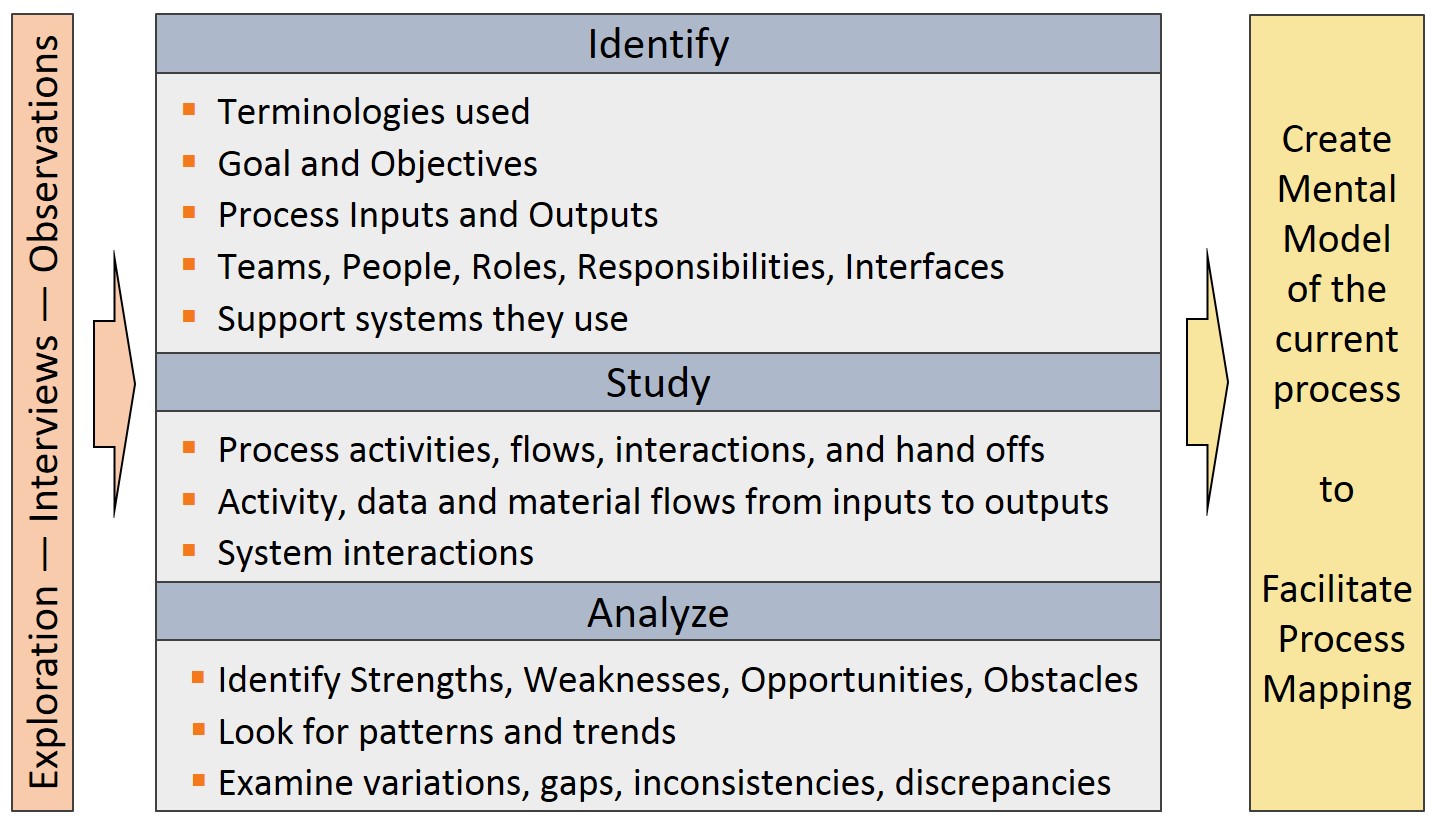

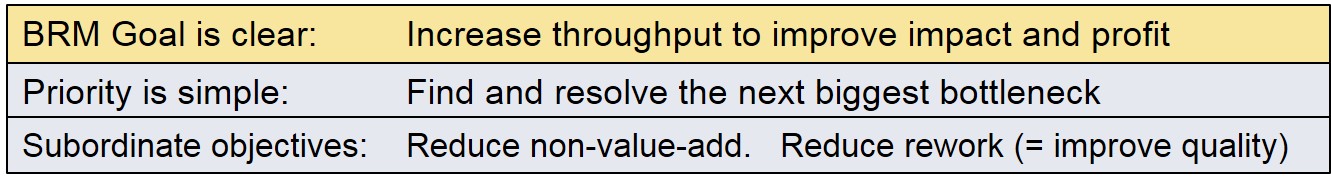

This goal requires increasing the quantity and quality and/or decreasing the cost. To accomplish these objectives, BRM uses concepts from the Theory of Constraints (TOC), Lean, and 6 Sigma, to the extent practical for teams with limited Process Improvement expertise. The graphic below shows the concepts that are incorporated.

BRM resembles TOC in that it first and foremost focuses on resolving bottlenecks, which are constraints that stop a process from producing more outputs. The priority is to find and resolve the biggest bottleneck. The next priority is to find and resolve the next biggest bottleneck, and so on. Bottlenecks are resolved by deploying alternate people, systems, methods, and workload distributions.

BRM integrates Lean's concept to eliminate superfluous activities that don't add value, and 6 Sigma's concept to reduce quality problems that cause rework activities. As non-value-add and rework activities take up time, they lower the output quantity and increase cost. Eliminating these activities frees up time that can then be used to resolve bottlenecks.

The remainder of this tab contains two chapters. The first chapter defines the key productivity drivers addressed by BRM. The subsequent chapter explain the BRM framework for improving productivity, which relies on a reasonable understanding of the productivity drivers.

Productivity Drivers

This chapter explains the key productivity drivers addressed by BRM, including throughput, bottlenecks, bottleneck resolution, utilization, efficiency, quality, and cost. This chapter also explains the relationship between these drivers and productivity.

Throughput

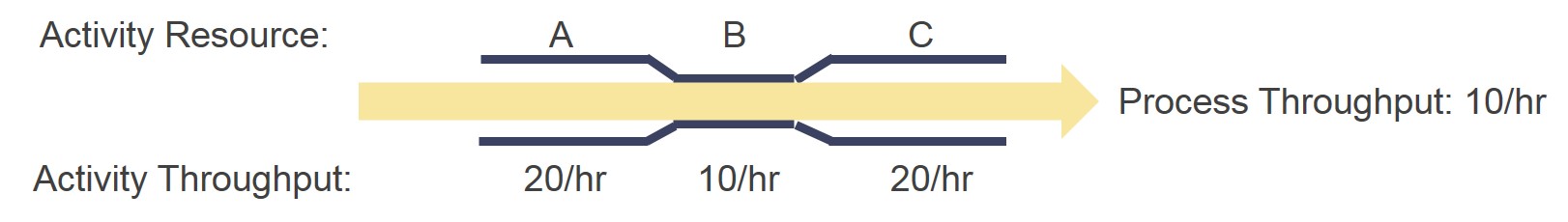

BRM's main focus is on increasing throughput. Throughput is defined as the output quantity produced over a defined period of time. For instance, 20 units per hour. Improving the output quantity of a process requires increasing the throughput of the process.

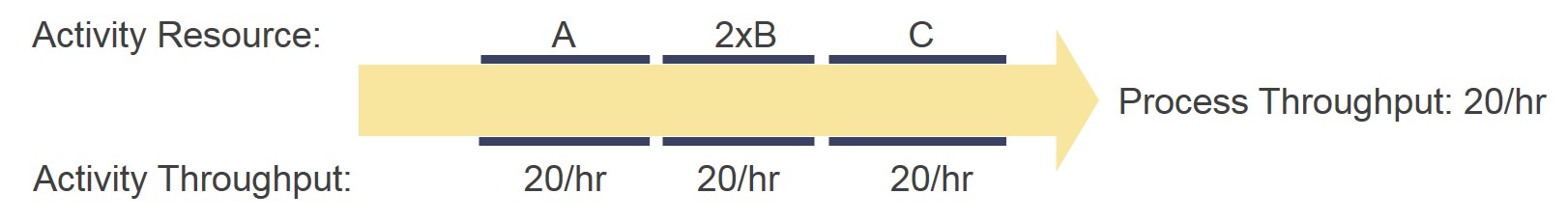

The process throughput is determined by the throughput of the activities that make up the process. Each activity has a maximum throughput, i.e. the maximum amount the activity can produce. If every activity in a process is executed in sequence to produce one unit of output, then the process can only produce as many units as the activity with the lowest throughput can produce.

For instance, assume process ABC consists of 3 activities A, B, and C to be executed in sequence to cure a patient. Assume the maximum throughput of A = 20 patients/hour, B = 10 patients/hour, and C = 20 patients/hour. The maximum throughput this process can produce is defined by B, which is 10 patients/hour.

This example is visualized below. The area between black lines represents the maximum throughput of activities A, B, and C. The yellow arrow visualizes the maximum process throughput as limited by activity B.

Bottleneck Resolution

To increase throughput, BRM focuses on resolving bottlenecks. A bottleneck is defined as a limitation or constraint in the process that restricts the overall throughput. Bottlenecks are inversely related to throughput. The activity with the lowest throughput is by definition the biggest bottleneck.

In the example above, activity B is a bottleneck, because it limits the throughput of the process to 10 patients/hour. If activity A would handle 20 patients/hour, this would create an inventory of partially cured patients queuing up in front of activity B. Activity C can never even cure 20 patients/hour, as it never receives more than 10 patients/hour from activity B.

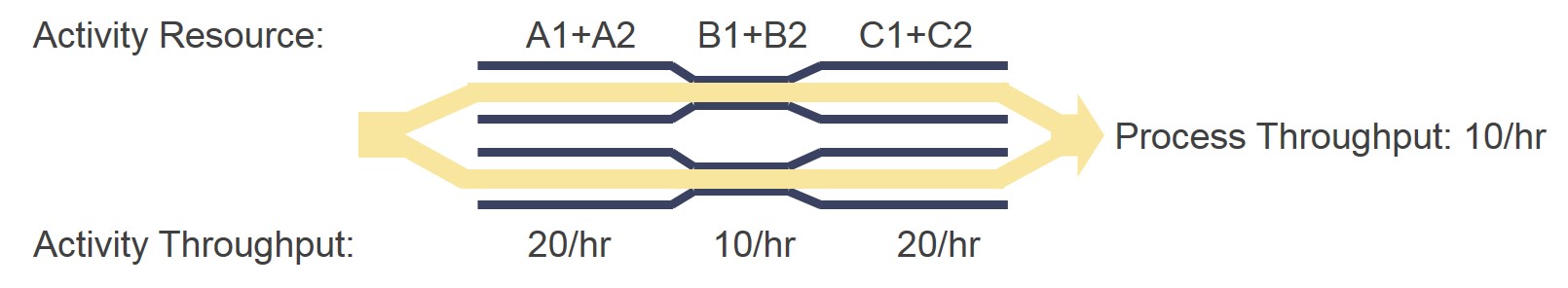

If you could double the throughput of activity B, the process throughput would increase accordingly. This would eliminate the bottleneck from activity B, as shown below. This could for instance be accomplished by simplifying the activity so it takes less time, or by assigning additional resources to increase the capacity.

Processes often have multiple resources to accomplish the same activity. In this case, the combined throughput of the resources that execute an activity determines the overall throughput of the activity. For instance, multiple people and/or machines can execute the same activity, which is visualized below. In this example, the two people who execute activity B are the bottleneck.

Bottleneck Resolution Order

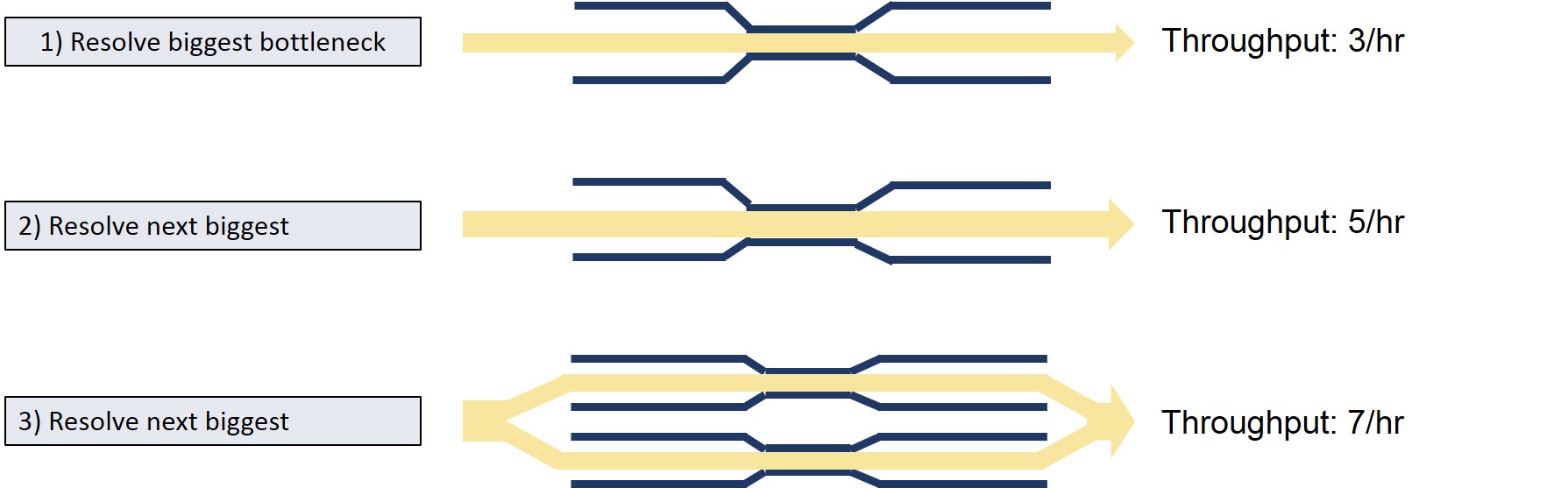

The core principle of BRM is to use the process map to determine the activity that causes the largest bottleneck, and to resolve this bottleneck first. This will typically cause another bottleneck to become the biggest, and that one should be resolved next, and so forth. This is shown below.

Don't aim to resolve all bottlenecks. There will be a diminishing return on the effort as the remaining bottlenecks will be smaller. The 80 20 Pareto rule applies: By first focusing on the biggest bottlenecks, resolving 20% of bottlenecks might resolve 80% of the throughput issues. This opens the door to keep things practical:

- Don't take "biggest" bottleneck too literally. Without measuring all the activity throughputs, which may not be feasible, it may not be clear what the biggest bottleneck is. Even if you can determine the biggest bottleneck, it might not be practical to resolve it first. The essence of "biggest" is to resolve bottlenecks where improvement will significantly increase the process throughput.

- Don't take "resolution" too strictly either. It is not necessary to fully resolve the biggest bottleneck. It can be sufficient to resolve the bottleneck to the extent it is no longer the biggest. Thereafter, it may be more productive to first resolve other large bottlenecks that have become the biggest.

Utilization and Efficiency

The main drivers of throughput are the utilization and efficiency of the resources deployed to execute the process activities. Bottleneck resolution largely focuses on increasing the utilization and efficiency of both the human and system resources.

- Utilization: is defined as the percentage of time a resource is busy executing their assigned process activities and other required business responsibilities. Utilization is a quantifiable measure. For instance, if the utilization of a physician is 80%, he/she spends 80% of the time on required activities. The remaining 20% is excess capacity available to be deployed elsewhere in the process.

If the utilization of a resource reaches 100%, the resource will likely become a bottleneck, unless the resource starts working overtime, which might be cost effective. For instance, if the cost of overtime is less expensive than adding people, allowing paid overtime can be an appropriate choice to avoid a bottleneck, but a better option would be workload redistribution.

Utilization often says little about whether a resource is efficient. A person that is 100% utilized might be inefficient in executing their tasks. For instance, young physicians may have a higher utilization than experienced physicians, but they are typically less efficient. Don't be fooled by high utilization, as sometimes people can be quite busy accomplishing little.

Bottlenecks inherently reduce the utilization of resources that execute activities that follow the bottleneck, because the bottleneck won't let enough output come through. So it is important to investigate who or what is the cause of low utilization. Is it the activity resource itself, or is it caused by a prior activity.

- Efficiency: is defined by how effective a resource is in executing their work. Efficiency can be quantified as the amount of work completed per time period spent on an activity. For instance, if a resource produces 100 units/hour and its utilization for this task is 50%, the efficiency of the resource for this task is 200 units/hour.

Both non-efficient and efficient resources can cause bottlenecks. Obviously non-efficient resources are more likely to cause bottlenecks, as non-efficiency reduces throughput. However, if the utilization of a resource is high, even an efficient resource can become a bottleneck as there simply isn't sufficient time in the day.

For resources that handle many different activities, the efficiency tends to be less measurable, as the outputs consist of many things. In this case, efficiency becomes a relative measure based on a subjective assessment. For instance, is the person focused on their tasks, how much does the person produce versus others, do the various outputs require a lot or little effort?

Quality and Cost

While BRM's main focus is on increasing throughput, the goal of BRM is to improve productivity, which is defined by the relationship between quantity, quality, and cost. High quantity and quality at low cost is productive, and low quantity and quality at high cost is unproductive.

There is no point in producing a large quantity if this comes with many quality defects, or at a cost that is too high. Just because people are efficient, doesn't guarantee they produce quality outputs, or vice versa. If doing it right the first time means doing it slowly, or with expensive resources, that isn't effective.

In other words, quantity, quality, and cost are related and cannot be improved in isolation. So when resolving bottlenecks to improve utilization and efficiency, take into account that all activities affect the output quality and that all activities come at a cost:

- Quality: can be expressed as the accuracy and precision of the outputs: Accuracy is defined as the average quality produced compared to the output specifications. High accuracy means the average quality meets specifications. Precision defines whether the quality is all the same (regardless of accuracy). High precision means the outputs are consistent in quality.

- Cost: is a function of Cost of Goods, Activity Cost, and Overhead Cost: Cost of Goods (CoGs) is the cost of materials that end up in the outputs. Activity Cost is the expense of resources and consumables deployed to execute the activities. Overhead Cost is the expense of related management, administrative and other overhead that doesn't add direct value to the outputs.

Productivity

To summarize, BRM defines productivity as the product of utilization, efficiency, quality, and cost. These four aspects are the main drivers to improve the process productivity at top level. Ideally, the aim is to drive utilization, efficiency, and quality up, and to drive cost down. However, the ideal solution may not be pragmatic and being pragmatic is important, otherwise the improvements might not succeed.

Being pragmatic requires making choices and introducing trade-offs. Sometimes it may be better to drive one aspect up at the expense of another aspect. For instance, when improving the efficiency, utilization can initially go down. Driving quality up too far can be overly costly, so good enough quality might be sufficient and more cost effective.

The remaining chapter on this tab defines the details of how to implement the BRM strategy. The main focus is on improving utilization and efficiency, but with a secondary focus on improving quality and cost.

There are typically many aspects at lower levels that influence these four main productivity drivers. To choose the right Process Improvement options, it will likely be necessary to dig deeper into what influences these drivers. Details of what aspects to look for are discussed in the implementation chapter below.

Productivity Improvement Framework

The sections below describe BRM's framework for improving productivity. The framework consists of three steps that expand on Process Mapping to define the improved future process. Steps 1 and 2 can typically be executed at the end of the Process Mapping session. Step 3 is best done later in a separate Process Improvement session.

The framework is intended as a resource to design real life improvements. The team will need to adapt and expand the options described in the framework to negotiate how the process will be improved. The "Negotiation tab" provides a negotiation strategy that is suitable for this purpose.

A word of caution for negotiating the improvements: Don't aim to design an ideal process. The objective is to define a pragmatic process that the team can actually make work, and that other stakeholders will support.

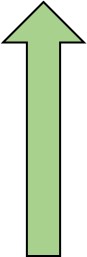

Step 1: Identify Bottlenecks, Non-Value-Add Activities, and Rework

The first Process Improvement step is to identify bottleneck, non-value-add, and rework activities. Finding these activities is key to improving the process with BRM. At the end of the Process Mapping session reevaluate the map of the current process and identify such activities. Look for the characteristics listed in the table below.

For the identified problem activities, determine whether they occur frequently enough to significantly lower the productivity. Ideally one should measure the impact, but teams can typically express whether things happen frequently and whether that causes major issues. As a first pass, this is sufficient to establish reasonable certainty whether there is a real issue or not.

| Activity | Identifying Characteristics | |

|---|---|---|

|

Explicit Bottleneck |

This activity causes wait queues and delays in front of the bottleneck, and idle time in the subsequent activities, while the bottleneck is busy at all times. For instance, if nurses can't keep up with preparing patients for surgery, the waiting room fills up with patients, and a surgeon may be idly waiting for patients. These are signs that the nursing activity is a bottleneck. |

|

|

Hidden Bottleneck |

This activity causes idle time in the activities before and after the bottleneck, while the bottleneck is busy at all times. This can happen when the activity before the bottleneck has been adapted to lower its output to avoid wait queues before the bottleneck. For instance, if the patient intake is adapted to the workload the nurses can handle, the nursing activity is still a bottleneck. |

|

| Non-Value-Add |

This activity produces things that add nothing to the outputs, aren't used by any other activity, and aren't needed to fill any legal or administrative business requirements. For instance, if two activities are located far apart and the outputs need to be transported from one activity to the other, the transportation adds no value if it could be avoided by co-locating the activities. |

|

| Rework |

This activity is executed to resolve quality issues, such as failures, errors, incompleteness, and other issues that cause variations in the process outputs. For instance, if Summary of Care (SoC) documents sent by a provider are frequently incomplete and require requests for updates, the activity to request and evaluate the updates is a rework activity. |

|

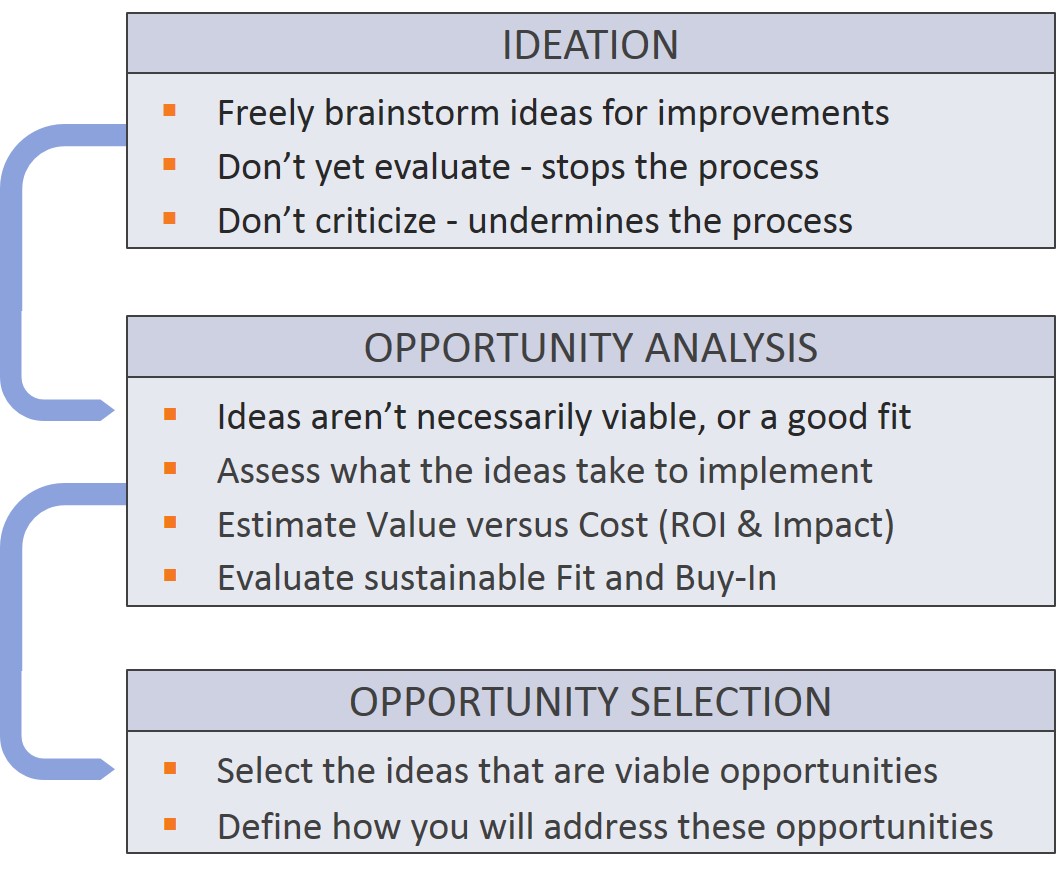

Step 2: Identify Productivity Improvement Opportunities

An easy way to resolve bottlenecks is to add resources. For instance, hire extra staff or buy an extra machine. This method is often used and frequently abused. It really should be the last resort after all Process Improvement opportunities have been exhausted. Adding resources, especially staff, is costly. It can also be ineffective and reduce capacity, for example when a lot of training is required.

Therefore in Step 2, first identify opportunities that improve the process without adding resources. Discuss ways to build on things that already work well. Look for opportunities to redistribute the workload or to use alternatives that improve the productivity of the existing resources. Step 2 is about identifying opportunities, and not about selecting the implementation, as that is done in Step 3.

Use the qualitative indicators in the list below to identify potential productivity improvement opportunities in the process map. The list is not exhaustive, but gives an idea of how to go about Step 2. The cost indicators overlap with the utilization, efficiency and quality indicators, because cost is an important aspect in making the right choices to improve the other three productivity drivers.

| Productivity Improvement Opportunity Indicators | ||

|---|---|---|

| Driver | Indicator | Description |

|

Utilization |

Frequently idle |

If resources are frequently idle this indicates that there is unutilized capacity that could be used for another activity. For instance, if nurse practitioners have idle time with nothing to do, this time could be made available to resolve that doctors have too much to do. |

|

Parallelism |

If the same activity is executed by multiple people in parallel, this indicates that there may be potential to move capacity between these people without training. For instance, if certain activities can be executed by both a nurse and a nurse practitioner, tasks can be shifted from one to the other depending on who is available. | |

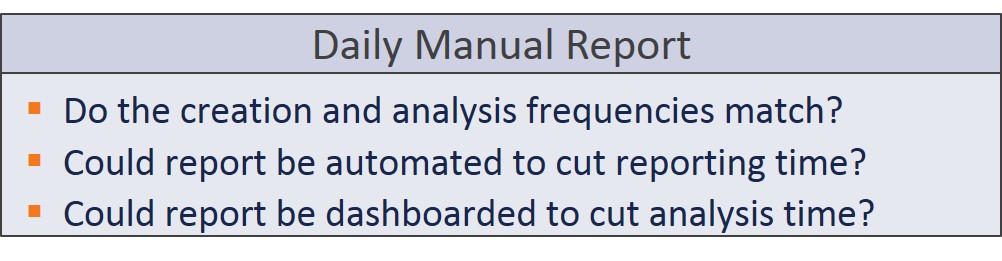

| Repetitiveness | If an activity is repetitive, fully or partially automating the activity could be an option. For instance, the manual creation of the same daily report could be replaced with an automated report to free up people capacity through a one time investment in software. | |

| Efficiency | Ineffectiveness | If a resource is ineffective in their work, there may be room to improve how or by whom the activity is executed. For instance, if a nurse isn't great at report writing, simplifying the report, training the nurse in report writing, or giving the task to someone else might resolve the inefficiency. |

| Simplicity | If an activity is easy to execute, there may be potential to move the activity to somebody less skilled. For instance, if the physician handles patient issues a Nurse Practitioner (NP) could handle, these tasks could be shifted to the NP to free up the physician's time for more complex issues. | |

| Complexity | If an activity is too complex for a person's capability, it can be better to either move it to somebody more skilled, or to simplify the activity. For instance, if the nurses struggle with a task and it takes too long, maybe the NPs could handle the activity more effectively, or the task could be simplified. | |

| Quality | Rework | If there is rework, the activities that cause the rework should be improved. For instance, requests for updates to incomplete Summary of Care documents could be resolved by improving the quality of the information exchange process between providers. |

| Inconsistency | If there is inconsistency in how a process is executed, this can result in quality discrepancies in the outputs. For instance, if a person is inconsistent in their execution, or if multiple people execute the same work differently, this can result in variations in the output. Inconsistency can be harder to discover during Process Mapping than rework. | |

| Cost | Under-utilization | Under-utilization makes resources relatively more expensive. Increasing their utilization will reduce the cost per output, even if this means using them to execute simple tasks. This can be cost effective if there isn't enough complex or unique work to keep them busy. |

| Misappropriation | If resources are assigned to tasks that could be handled by less expensive resources, reassigning these tasks might reduce the cost. However, that isn't the case if that simply makes the more expensive resources under-utilized, so in parallel more complex work should be assigned to them. | |

| Ineffectiveness | If a resource is ineffective, the time spent on executing their work will be excessive and this increases the cost per output. Either train or coach the resource to become more effective, or reassign tasks between resources to align the work to their capabilities. | |

| Inconsistency | If resources are inconsistent in their execution, this can cause quality problems which inherently will cause rework or repair cost. Either train or coach the resources to become more consistent, or reassign tasks between multiple resources to align the work to their capabilities. | |

Step 1 and 2: Add Colored Dots to the Process Map

A good way to record the issues and opportunities in the process map is to place colored dots where they occur with a note of what was identified. These dots will aid in the Process Improvement Step 3 that follows. Use different colors for the bottlenecks, non-value-add activities, rework, and opportunities.

Step 1 and 2: Process Map Illustration - Part 2

Let's go back to our process map illustration shown at the end of the "Process Mapping" tab. Assume that the following observations were made, which are highlighted in the map below with colored dots:

Bottlenecks:

- The NP struggles to keep up with conducting the triages, causing a wait queue of patients.

- The NP also can't keep up with treating patients.

Non-Value Add:

- The reconciliation report created by the Nurse is not used by anyone, because others can see the reconciliation within the patient's EHR record.

Resolution Opportunities:

- Reconciling the C-CDAs could be partially automated.

- Discharge C-CDAs are sent by the NP, but the Nurse is capable of doing that too. Could the Nurse handle the NP's discharges?

- The Nurse instructs the patients seen by the doctor. This probably implies that the NP instructs her own patients even though this isn't shown in the map. Since instruction takes up NP time, could the Nurse handle the NP's instructions too?

Note: These last two opportunities assume that the Nurse has time to handle this extra work, and/or that Nurse time can be freed up to handle these tasks. Before the process can be improved, this needs to be verified. How to potentially do that with metrics is the topic of the "Productivity Metrics" tab.

Step 3: Resolve Bottlenecks, Non-Value-Add Activities, and Rework

The next step in the Process Improvement is to determine how to best resolve the identified issues. In Step 3, bottleneck resolution is the main priority, but the value-add optimization and rework/variance reduction are secondary objectives executed in parallel.

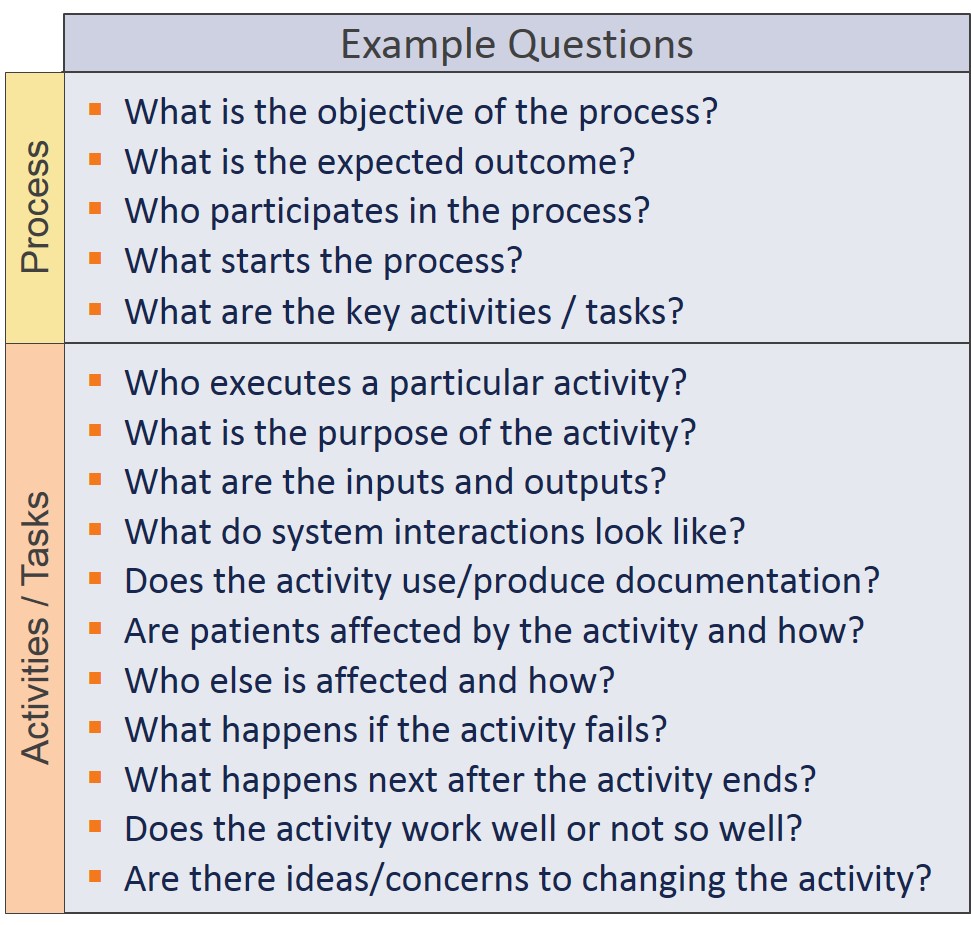

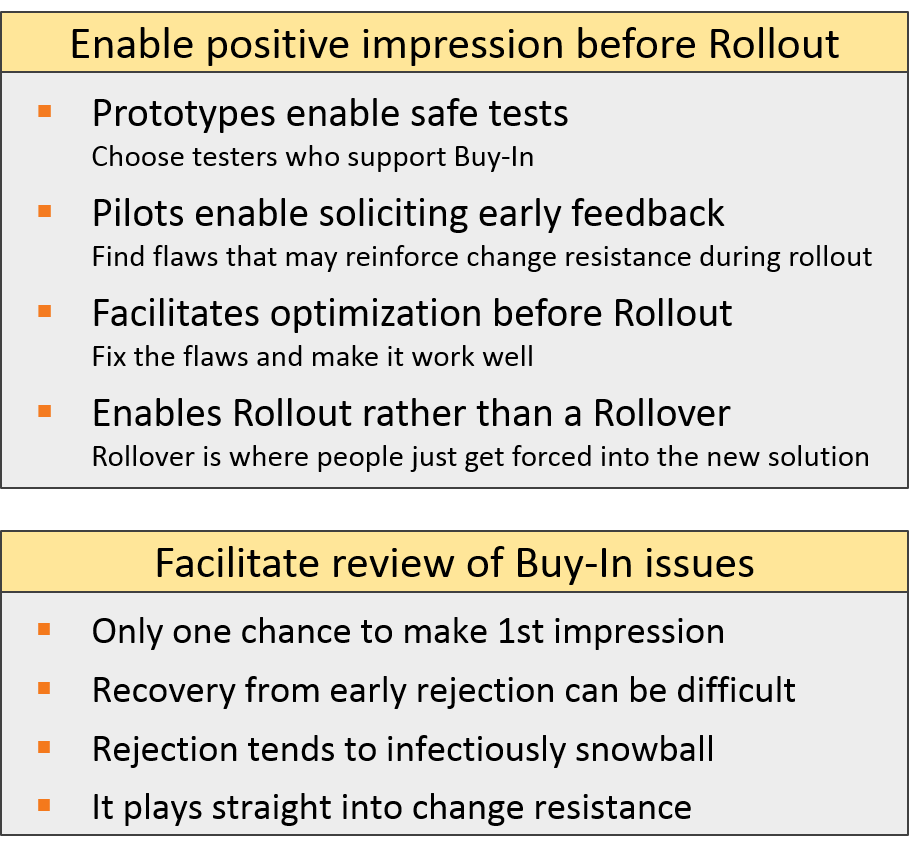

Schedule a Process Improvement session with the team to discuss how the process will be improved. Let them suggest how it can be done as that increases buy-in and enables motivation to make it work, but stimulate them to build on what already works rather than reinvent the wheel. Update the process map based on the agreed upon improvements to reflect how the process will work going forward.

The graphic below highlights a range of alternative options to improve a process. These options are explained in more detail and exemplified in the next three sections.

Bottleneck Resolution Options

Bottleneck resolution deals with increasing throughput by improving the utilization and efficiency of the people and systems involved. After the bottlenecks that cause waiting, delays, idle time, and other throughput reducing issues have been identified, start the sequence of resolving the biggest bottlenecks. Use the following options for this purpose:

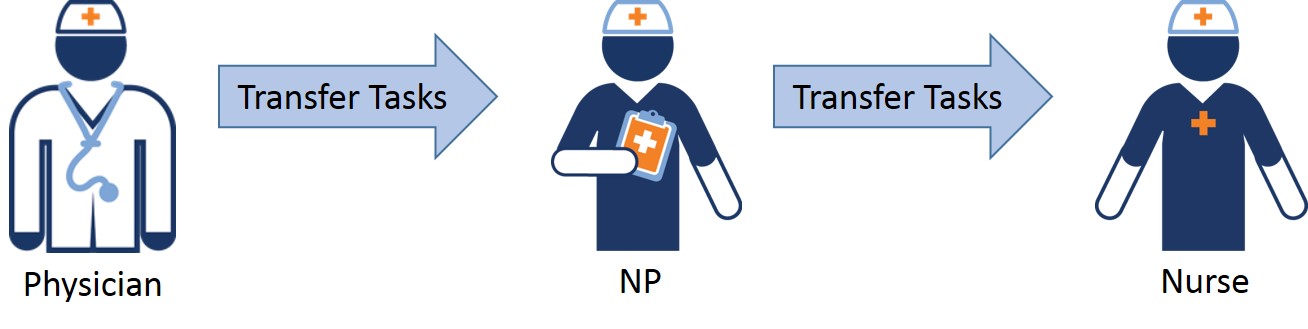

- Offload lower skill tasks from expensive or unique resources to increase capacity

If an expensive or unique resource causes a bottleneck, offload some of their activities to an alternative resource that isn't fully utilized. Shift the activities down the capability curve as necessary to resolve the bottleneck, as shown in the graphic below.

For instance, if a doctor is a bottleneck, offload some cases down to a Nurse Practitioner (NP) who can handle these cases.

It can also help to offload up rather than down. This may feel counterintuitive, but can be quite sensible. For instance, if a nurse with a unique skill has too much work, and an NP has idle time, offloading tasks from the nurse to the NP might solve the issue.

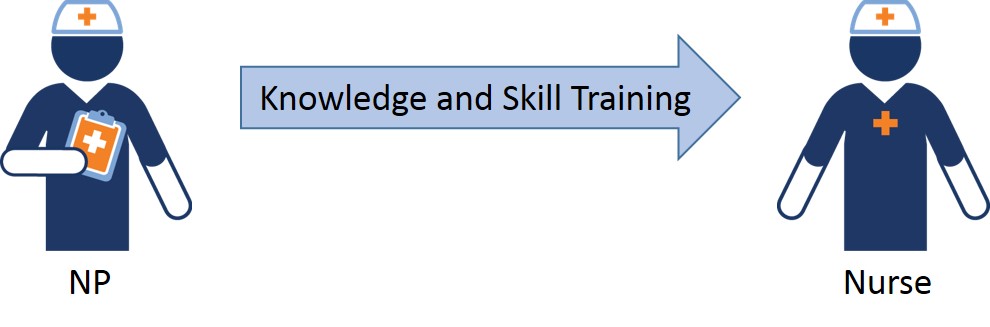

- Use the experienced resources to train less experienced resources in tasks to be offloaded

To make offloading work, the experienced or unique resource may need to train the alternate resource. For instance, the doctor can train the NP. Initially this increases the workload, but this temporary issue tends to pay off in the long run.

- Increase utilization of underutilized capacity to handle the offloaded tasks

The idea behind the previous two options is to offload tasks to underutilized resources, so that the workload becomes more balanced. However, the best alternate resource may not have time to handle more work. In this case, offloading tasks through multiple experience levels can be a solution.

For instance, assume the doctor is overloaded but the NP has no free capacity. In this case, the NP may first have to offload tasks down to a nurse who has excess time available.

These first three options move job responsibilities around to stimulate productivity, but potentially also enable career growth for employees. When reassigning work make sure to select employees who can be trained to execute the work. It is counterproductive to put employees in spots they can't possibly handle. Putting square pegs in round holes will lower the productivity.

Note that these three options also apply to machine and computer resources. Some devices or systems may have more capabilities than others. Reassigning how and when these are being used can free up capacity of the extra capabilities if those cause a bottleneck. For instance, one diagnostic device could have special features that another device doesn't.

- Enhance the support systems to free up people capacity and optimize utilization

If a machine or computer system is difficult to use, lacks capability, or has insufficient capacity, this can consume the time of the people who use the system. If this contributes to bottlenecks, consider making an investment to enhance the system with new and/or easier-to-use functionality to free up time.

For instance, if an EHR is hard to use or requires too many steps, an upgrade or add-on technology might alleviate the issue.

For example, if an old MRI or CT Scan system takes too long, could it be upgraded? If an EKG or ultrasound system doesn't provide enough capacity, can adding another system resolve the issue?

- Automate time consuming and/or repetitive tasks to free up people capacity

Automating parts of a manual process with technology can be especially effective for tasks that are repetitive, time consuming, and error prone. Systems can often handle such tasks more effectively. The idea here is not to replace people, but to elevate what they do, so they have more time for tasks that require human expertise and interactions.

For instance, if a daily report is created manually, replace it with an automated report or dashboard that can be easily analyzed.

Value Add Optimization

For optimal efficiency at the lowest possible cost, the activities in a process should either add:

- value the customer is willing to pay for (e.g. clinical treatments), or

- value to the business (e.g. legally required accounting activities)

Use the following options to eliminate superfluous activities that don't add value, and to optimize activities that do add value:

- Eliminate unnecessary tasks that don't add value to the customer or the business

Activities that neither add customer nor business value should be eliminated. This frees up capacity, which can then be used to resolve bottlenecks.

For instance, if not having sufficient medical devices causes the staff to spend a lot of time moving the devices from room to room, adding some devices can eliminate the time wasted on moving things around, which is an activity that doesn't add value to making patients better.

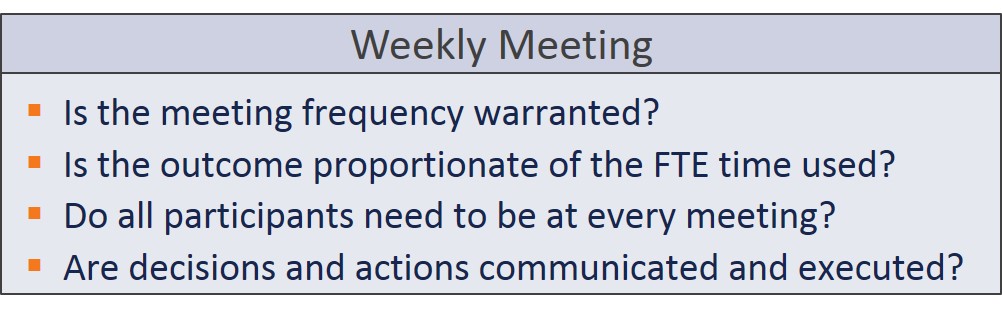

For example, consider process ABC again. Assume the person who executes activity B uses 50% of the time to address tasks that don't add value, such as attending irrelevant weekly meetings. By eliminating these superfluous tasks, the person can handle more patients per hour, which reduces the bottleneck of activity B.

For instance, assume activity B includes a daily report that is only used on a weekly basis. Reducing the report frequency to how often the report is actually used will free up time, which can be used to increase the throughput of activity B.

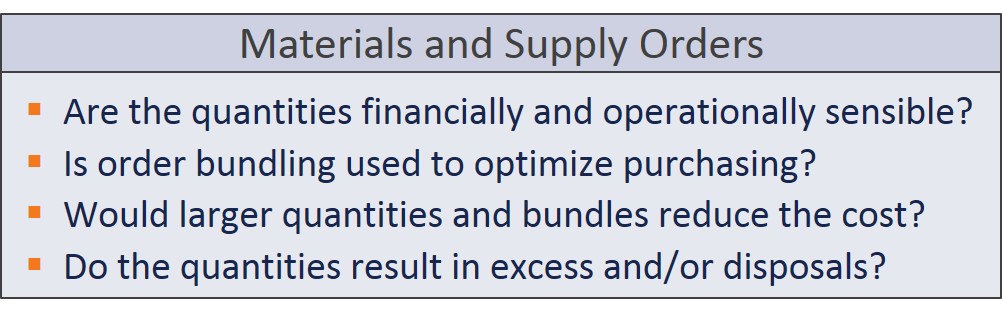

- Improve capacity and quality of tasks that add customer value or business value

It is important to optimize the activities that do add value, so the available time is effectively used to create quality outputs. If an activity isn't well organized, frequently duplicates efforts, produces low quality, creates excess quantities, or results in other value reducing issues, then the activity should be restructured.

For instance, if activity B involves ordering materials and supplies and this activity doesn't make use of common purchasing best practices, then improving this task could improve the throughput of activity B.

- Decrease WIP (Work In Progress inventory) to increase throughput

WIP refers to partially completed results that flow through the process towards completion. In process ABC, WIP consists of partially cured patients. Creating WIP beyond the process capacity doesn't add value, as this WIP can never flow to completion. The time spent on creating WIP would be better spent on offloading activities that cause bottlenecks.

For instance, the person that executes activity A, could spend part of his/her time on activity B. That reduces capacity for activity A, but increases capacity for activity B. It also reduces the WIP that activity A can produce.

- Increase WIP (Work In Progress inventory) to increase throughput

Conversely, a temporary increase in WIP may actually increase the throughput. It can compensate for down time where a resource is temporarily unavailable. It can also offset variations in how long a subsequent activity takes.

For instance, assume the person who executes activity A now also works activity B. That only helps if the person produces temporary WIP while working on activity A that gets processed during the time he/she works on activity B.

Rework Reduction

Low quality and variations in quality tend to result in rework, e.g. to ensure that all outputs fall within the required specifications or expectations. Rework reduction is about eliminating the causes of quality issues. Reducing rework will free up time that can be used to resolve bottlenecks, as time not spent on rework can be spent elsewhere.

Rework that is identified during Process Mapping is easier to resolve than rework that happens behind the scenes and isn't mentioned during mapping. For instance, if a lab technician frequently fails to draw blood in the first pass, this might not be apparent beyond the patients who experience frequent needling.

Use the following option to resolve rework that has been explicitly identified:

- Reduce rework by improving the quality of work

If rework happens a lot, then reduce the rework by identifying and resolving the related quality issues that cause the rework.

For instance, the team might indicate that incoming Summary of Care (SoC) documents for referrals may be incomplete and how that would be handled. The solution could be to improve the information exchange process with the referring provider.

For example, if a patient isn't fully diagnosed correctly, then surgery might not completely resolve what is wrong with the patient, and follow up surgery might be needed. If the follow up surgery could have been avoided, then this is unnecessary rework.

For instance, if a diagnostic device is not calibrated properly or intermittently fails to produce the right result, this could cause misdiagnosis or other quality problems. A recalibration and maintenance schedule could be instated to overcome such issues.

Variance Reduction

Inconsistencies in the process can cause variations (variances) in all four aspects of productivity, i.e. utilization, efficiency, quality and cost. While the average productivity may look solid, the variances can add up to significant issues over time. While increasing the average productivity, you also need to reduce these variances.

For instance, if the utilization and efficiency fluctuates, this can result in transitory bottlenecks that temporarily lower the throughput. Use the following option to reduce the variances:

- Reduce variances by improving the consistency of work

If inconsistencies are substantial, then determine and resolve the causes of the inconsistencies. The bottleneck resolutions options can also be applied to address inconsistency issues.

For instance, if some of the work is too complex for a resource to handle, provide training or reassign the work. If two parallel resources execute the same work differently, use Process Mapping to align how they operate. If a temporary heavy workload causes a decrease in consistency, redistribute the workload.

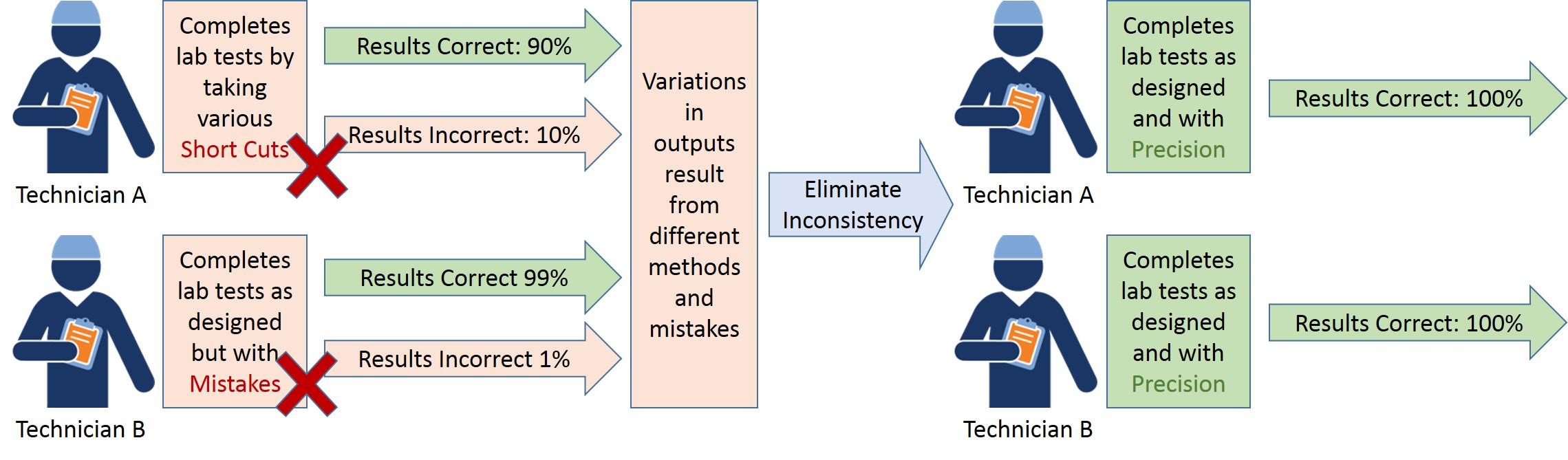

For example, if two lab technicians execute lab tests in different ways, as shown below, then aligning how they execute the tests can reduce the variances in their test results (their outputs).

When to start using Productivity Metrics

As stated before, the main value of BRM comes from the discussions between the team members. These discussions will align the perceptions, help identify issues and opportunities, and facilitate defining resolutions. Typically you can reasonably complete the above steps without metrics, based on the qualitative impressions and anecdotal evidence identified in the discussions.

However, as the improvements progress, it can become important to have some Productivity Metrics to quantify the impact of the issues and opportunities identified. For instance, to measure the impact of a bottleneck, or the frequency of rework. Having suitable Productivity Metrics can facilitate selecting the most pragmatic and effective resolutions.

Learn more about metrics in the "Productivity Metrics" tab.

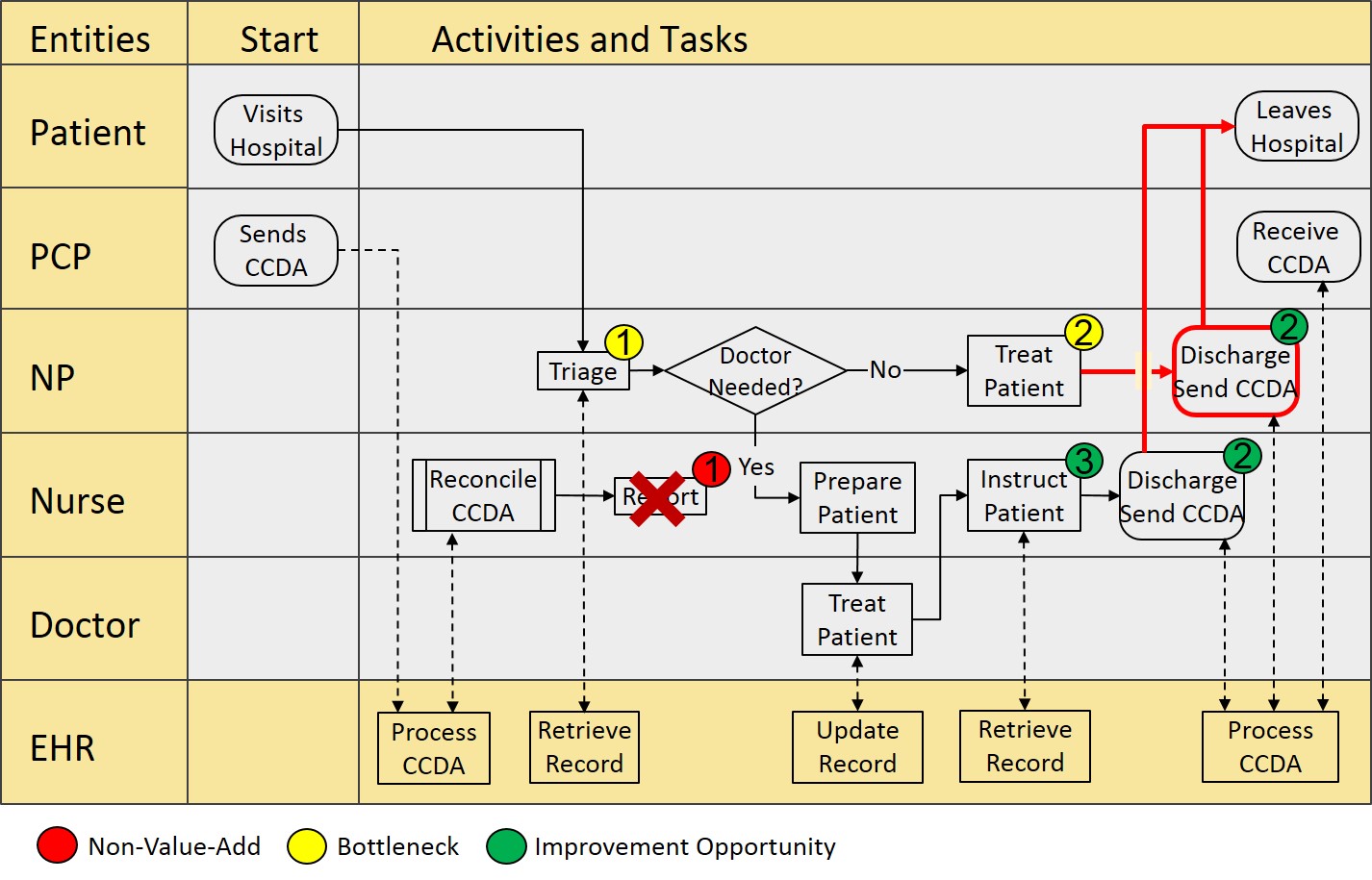

Step 3: Process Map - Illustration Part 3

Let's get back to our process map illustration shown at the end of Step 2. Assume that the workload is unevenly distributed, and that it is clear that the NP is overloaded (bottleneck) and the Nurse has time to handle extra work (opportunity).

Given the issues and opportunities identified, the team could improve the process and workload distribution as follows:

- Eliminate the reconciliation report, since nobody is using it.

- Reassign the discharges and sending the C-CDAs from the NP to the Nurse.

- Reassign instructing the patients from the NP to the Nurse.

The first change will free up even more Nurse time since it eliminates a non-value-add activity. The last two changes will free up NP time for triage and treating patients, so these changes will at least partially resolve the bottlenecks those activities caused. These improvements are illustrated below.

Now let's assume that the NP still doesn't have enough time to complete her tasks, but that the Doctor actually has excess capacity. This probably means that the NP is assigning too many patients to him/herself.

This may be due to the criteria defined for assigning who treats what patient. The potential solution is then to change the assignment criteria, so that more patients are seen by the Doctor. This is an example of reassigning up rather than down the experience curve.

Metrics

One can use qualitative impressions and anecdotal evidence to identify bottlenecks, non-value-add activities, and rework. In fact, during Process Mapping participants will typically voice that bottlenecks, wasteful activities, and rework happen. This qualitative data can be sufficient to make reasonable improvements, but may not be sufficient to refine the improvements.

A more advanced approach is to use Productivity Metrics that measure the various aspects that drive productivity. Such metrics can support the decisions how to improve the process, and the verification that the improvements are working. For this purpose, the metrics must provide quantifiable measures of performance and progress.

Productivity Metrics can be used to measure aspects that drive utilization, efficiency, quality, and cost. The best metrics are Specific, Measurable, Achievable, Relevant, and Time-bound (SMART) as explained in the table below. The definition of SMART varies in literature, but common aspects are that SMART Metrics support the objectives, can be measured and trended, and can be used to act.

| Criteria | Description | |

|---|---|---|

|

Specific |

Targets a specific and well-defined aspect that supports the objectives |

|

|

Measurable |

Quantifiably measures the current status and future progress |

|

| Achievable/Actionable |

Focuses on an aspect that is achievable, and yields data that can be acted upon |

|

| Relevant/Realistic |

Measures a relevant aspect that can realistically be improved |

|

| Time-bound/Timely | Is measured on an interval basis during a defined period of time | |

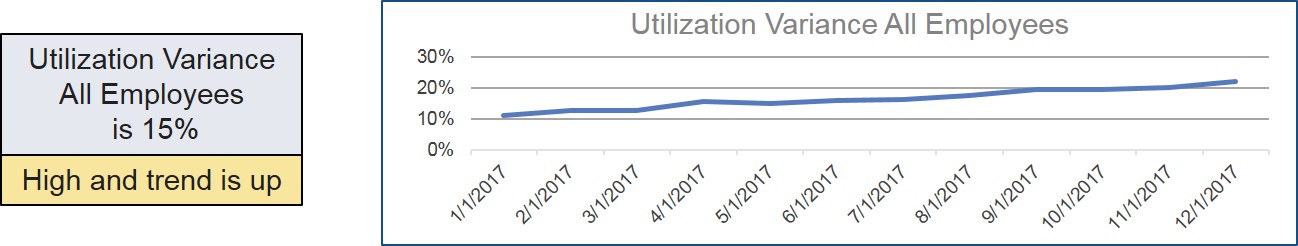

Averages, Variances, and Trends

In a metrics-supported process improvement strategy, there are three parameters to consider for each metric: average, variance, and trend. These parameters deal with process variations in throughput, quality, and cost. This works as follows:

- Averages

Averages indicate the typical result. Averages can indicate that on a general basis things are well or problematic.

For instance, if the employee utilization on average is 95%, that seems good. On the other hand, a 60% utilization would be problematic as it indicates a lot of unused resource capacity, which is costly.

- Variances

Averages can hide or overstate problems as there may be pockets of problems that average out. Variance indicates how much and how often results deviate from the average. The higher the variance, the more this indicates that pockets of problems exist.

For instance, with an average utilization of 95%, some employees may work overtime while others have down time. If overtime means extra pay, this makes the process more expensive. The variance in the utilization of the various employees can confirm that this is going on. If the variance is high, the indicates an opportunity to redistribute work to balance the workload.

- Trends

Trends are patterns that indicate whether things are improving or getting worse. Averages and variances are a snapshot in time, and can hide or overstate performance issues. Trend analysis tracks how the averages and variances change over time, and can be used to prioritize the resolution of issues.

For instance, if overtime pay is increasing, this indicates a more urgent and growing problem than when overtime pay is stable.

For example, if the trend is that the NPs are getting increasingly overloaded, while the nurses have more and more idle time, this means that the NPs are a bottleneck that can potentially be resolved by offloading work to the nurses. This trend would confirm the workload distribution assumption made in the first paragraph of illustration part 3 in the "Process Improvement" tab.

Utilization and Efficiency Metrics

Utilization and efficiency metrics provide a quantitative means to evaluate the size of the bottlenecks and to determine what resolution options can result in a significant improvement. Use these metrics to enhance the bottleneck resolutions:

- Increase the average utilization and efficiency

If the averages are low, use the bottleneck resolution options to increase the efficient utilization of the resources.

- Decrease variances in utilization and efficiency

If the variance from the averages is high, use the bottleneck resolution options to reduce these fluctuations.

- Reverse negative trends in utilization and efficiency and build on positive trends

If the averages are going down and the variances are going up, use the bottleneck resolution options to reverse this trend.

Quality Metrics

Quality metrics offer a quantitative means to evaluate quality issues and to determine how rework and variance reduction could result in a significant improvement. Use these metrics to enhance the resolution of low quality or variations in quality:

- Increase the accuracy

If the accuracy is low, increase the average quality by resolving the causes of low quality.

- Increase the precision

If the precision is low, decrease the variance in quality by making the process more consistent.

- Reverse negative trends in quality and build on positive trends

If the accuracy and precision are going down, adapt the process to reverse this trend.

Cost Metrics

Cost metrics offer a quantitative means to evaluate whether the current process is cost effective, and to determine how Process Improvement could affect the cost. Use these metrics to resolve cost issues:

- Decrease the average cost

If the cost per unit of output is high, reduce the cost by improving the utilization, efficiency, and quality while taking cost into account.

- Decrease the variance in cost

If the variance is high, decrease the variance by resolving the utilization, efficiency and quality causes of these variations.

- Reverse negative trends in cost and build on positive trends

If the cost average is going down and the variance is going up, use the bottleneck resolution options to reverse this trend.

BRM deals with cost improvement mostly from the perspective that if you increase the throughput and quality without adding new resources that the relative cost per unit of output will go down. However, if pervasive cost issues exist, then a more substantial financial analysis should be deployed. This analysis goes beyond the scope of this toolkit.

Detail Level Productivity Metrics

To enable Process Improvement, it may be necessary to measure more detailed metrics at the activity and process level. The table below lists metrics that can be relevant to improve the four productivity drivers. The arrows indicate whether to improve them up or down.

| Productivity Metrics | |||

|---|---|---|---|

| Driver | Metric | Description | Improve |

|

Utilization

|

Utilization |

% of Time spent working |  |

|

Idle time |

% of Time spent not working |  |

|

| Wait time | % of Time spent waiting for something to finish |  |

|

| Overtime | % of Paid Time spent beyond regular hours |  |

|

|

Efficiency

|

Throughput | Number of output units produced per time period |  |

| Cycle time | Time it takes to produce one unit of output |  |

|

| Overhead time | % of Time spent on required overhead tasks |  |

|

| Non-value-add time | % of Time spent on activities that add no value |  |

|

|

Quality

|

Accuracy | Average quality that is produced compared to the output specifications |  |

| Precision | Degree of variation (variance) in output quality (regardless of accuracy) |  |

|

| Rework frequency | Frequency of how often the rework happens |  |

|

| Rework time | % of Time spent on rework |  |

|

|

Cost

|

Cost of Goods (CoGs) | Cost of materials incorporated into the outputs |  |

| Activity Cost | Expense of time spent on activities plus cost of consumables and supplies |  |

|

| Overhead Cost | Cost of the time spent on required overhead activities |  |

|

| Contribution Margin | Sell price minus cost of one output (Indicates whether the cost is high) |  |

|

Key Performance Indicators (KPIs)

Organizations often measure many metrics, but this can become overwhelming to employees, which is counterproductive. Using many metrics simultaneously for decision making is not practical. It might even obscure what actually results in real improvements. It is also unlikely that many metrics will be immediately relevant to the Process Improvement objectives.

The graphic on the right shows metrics that may be useful for Process Improvement. That is a lot of metrics to deal with, and additional metrics might be needed to measure process performance against business objectives. For instance, clinical metrics to measure the quality of the clinical outcomes.

To solve the overload issue, it is good practice to focus on a few metrics first as Key Performance Indicators (KPIs), and to add or replace KPIs as the improvements progress.

KPIs are context driven metrics that specifically measure success and alignment with the most important objectives. A good number is to focus on three or five KPIs.

The metrics highlighted in yellow are often good KPIs to start with. The other metrics can move in and out of the picture, as the Process Improvement progresses.

As BRM incrementally improves the process in bottleneck resolution cycles, it suitably supports limiting the number of KPIs that are in play at any time. For each subsequent cycle, different KPIs can be selected and prior KPIs can move into the background depending on the current objectives.

One will likely not know up front which metrics will be used as KPIs, and historic data will be needed for future KPIs to be meaningful. It is therefore still useful to measure additional metrics well before they become KPIs. Just don't present them all to the team each day, as they will likely stop paying attention to any of it.

Using Metrics to support Decisions and Actions

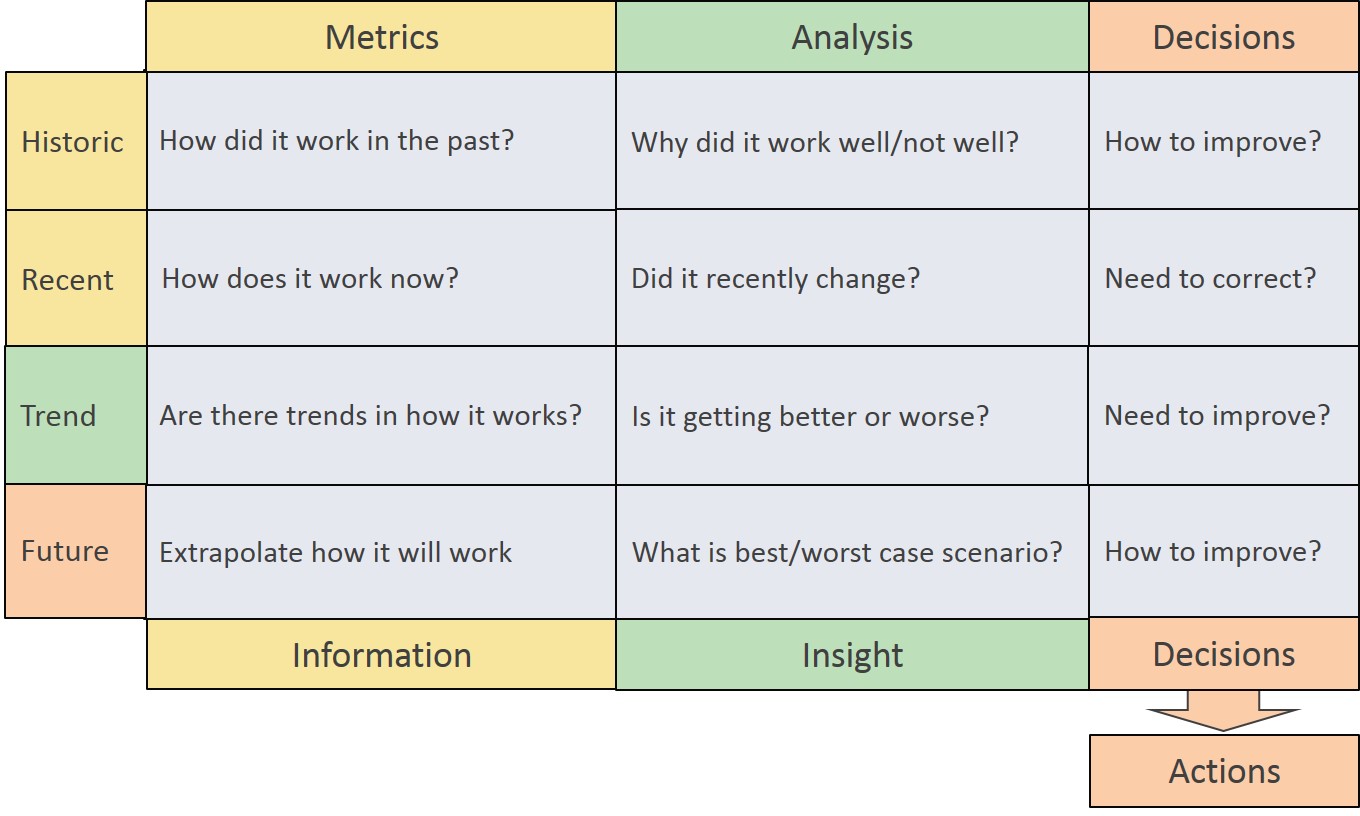

Consider the Productivity Metrics again. There is a dimension in the timeline that reflects that processes change over time, and that there are long and short term changes. Metrics can be used to measure the historic and recent process performance, and this information can be extrapolated to forecast the future performance. This time distinction can enable better improvement decisions.

The graphic below shows how each part of the metrics timeline can assist in the decision making. For instance, a metric might indicate that historically there has been an issue that should be resolved through Process Improvement. A metric might also indicate that something started to happen recently and that this simply needs to be corrected.

Forecasting is not an exact science and should not be done as a single prediction, as predictions rarely come to full fruition. That will invariably make you either fail or far exceed expectations. Neither will look good to management as it makes it look like you don't know what you are doing.

When making predictions, develop best and worst case scenarios to forecast the future as a range. As things progress, keep measuring the metrics and monitor the reality versus the predictions to study the effects of the implemented improvements. Adapt the process again if things don't work as anticipated.

Graphical Dashboards

When you measure a metric over time this tends to create a lot of data, especially as the measurement frequency increases. For instance, measuring once per day produces 365 data points per year, but measuring once per hour, yields 8,760 data points per year.

It is typical for the raw data points to be tabulated along the time axis, for instance in Excel or a metrics tool. While this is a great way to track the raw data, analyzing data tables to study averages, variances, and trends can quickly become overwhelming and is inefficient for most people.

A far more practical approach is to create dashboards that graphically represent the data. Especially when it comes to analyzing trends, a picture can truly tell a thousand words. For instance, the average, variance and trend graphs for the selected KPIs could be included in a KPI dashboard. This will provide a quick view on the performance measured by the KPIs.

Advanced Metrics Topics

The topics below go into more sophisticated detail in how to use and interpret Productivity Metrics. These aspects can be important for more advanced Process Improvement.

Statistical Variations

The example graphs of the averages, variances and trends displayed above show nice smooth patterns over time. It is rare that measured data actually looks so evenly distributed.

Besides the process variations that can be controlled, processes are prone to statistical variations that cannot be controlled. These variations cause the data points to fluctuate up and down at a much higher frequency than what is shown in the graphs.

For instance, the number of patients seen each day will vary; patients have different ailments and may require more or less time; the need for resources like medical devices and staff will vary depending on the patient; staff knowledge and efficiency will depend on the case; staff might call in sick, et cetera. These things just happen and the process has to deal with it.

Statistical variations will cause the process average and variance to fluctuate, and will obscure the trends. Look for instance at the top left graph below, which includes such statistical variations.

Trend Analysis versus Statistical Variations

There are several ways to bring out the trend information hidden in data with statistical variations. Which method yields the most valuable results may depend on what is being measured versus the level of detail needed to draw proper conclusions. The following trend analysis methods are commonly used: